Frequently asked questions

Company News

- Fluorocarbon aluminum veneer: the fashionable new favorite in the aluminum industry

- Aluminum veneer customization, create your personalized space

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

- Customize aluminum veneer to create personalized space art

- Aluminum alloy air conditioning cover: the guardian of coolness in summer homes

Industry dynamics

- Installation techniques and precautions for aluminum veneer

- In depth analysis of aluminum veneer customization industry

- Is the surface treatment of aluminum veneer durable?

- Aluminum veneer: the new darling of the industry, revealing its secrets!

- Aluminum alloy air conditioning cover: the guardian of coolness in summer

Frequently asked questions

- What are the manufacturers of aluminum veneer and how to choose?

- How to improve the environmental performance of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What is the price of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production process of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 22, 2025 01:16:34

- Click:0

What is the production process of aluminum veneer?

Aluminum veneer, as a high-quality building curtain wall material, has the characteristics of light weight, corrosion resistance, and fire resistance, and is widely used in modern buildings. So, what is the production process of aluminum veneer? Below, we will elaborate on four aspects in detail.

1、 Material preparation of aluminum veneer

Firstly, the production of aluminum veneer requires sufficient preparation of aluminum materials and related auxiliary materials. Aluminum materials usually use aluminum alloy materials with a purity of over 98.5%, while auxiliary materials include topcoat, primer, filler, etc. In the process of preparing materials, strict quality inspection is required, and different colors and properties of topcoat and primer should be prepared according to the predetermined proportion to ensure the quality of subsequent production.

2、 Production process of aluminum veneer

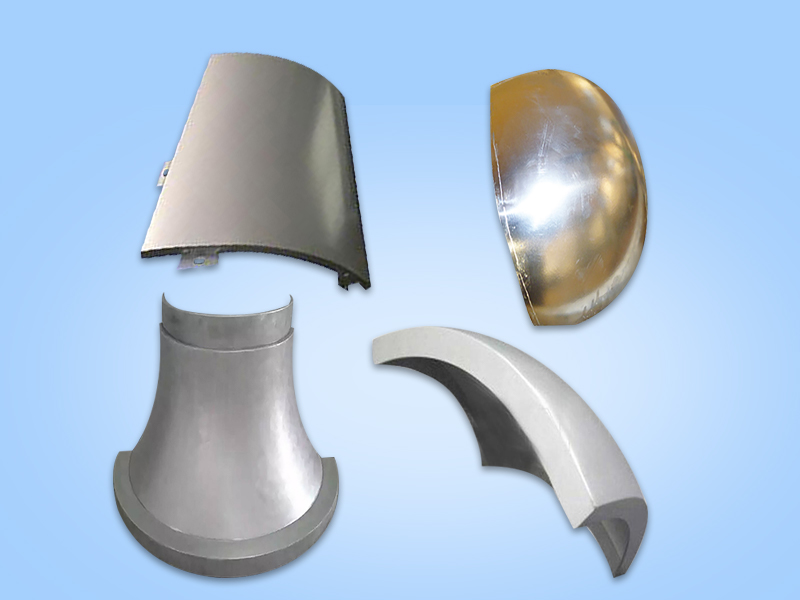

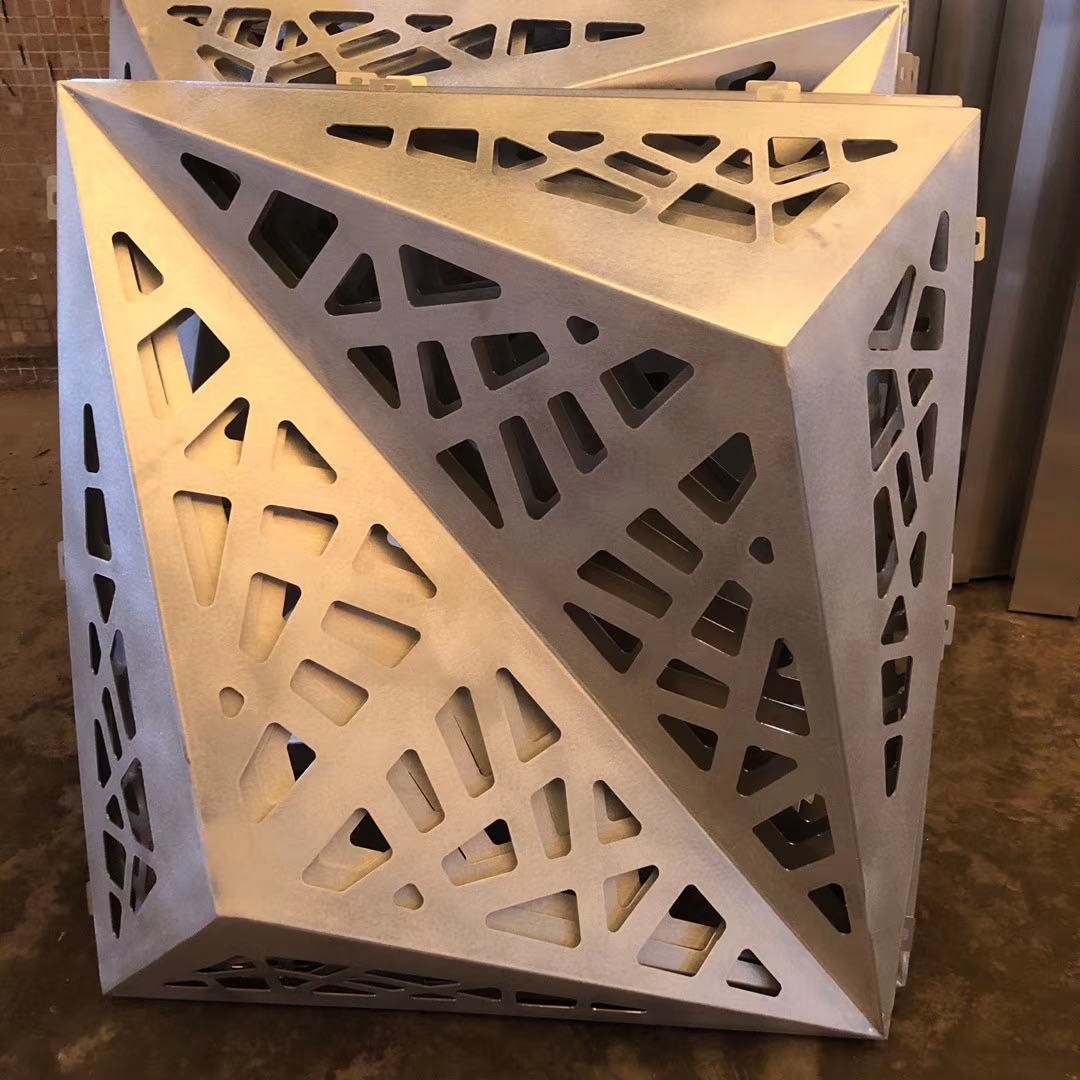

The production process of aluminum veneer can be roughly divided into: topcoat spraying, primer spraying, filler coating, drying, embossing, cutting, packaging and other links.

Firstly, the surface of the aluminum veneer is treated with a topcoat spraying equipment to make it smooth. Then, apply primer coating to enhance the corrosion resistance of the aluminum veneer. Next, apply fillers on the surface of the aluminum veneer as needed, which can be inorganic, organic, or composite materials. Subsequently, the aluminum veneer is sent to the drying room for drying. Reuse different embossing molds to embossing the dried aluminum veneer to create different patterns and textures on its surface. Finally, cut and package the aluminum veneer according to the design requirements.

3、 Quality inspection of aluminum veneer

After the production of aluminum veneer is completed, strict quality inspection is required to ensure the product's qualification rate. The main inspection items include surface flatness, color, corrosion resistance, hardness, etc. For this purpose, professional testing instruments need to be used to measure and analyze the samples to determine whether their quality meets the requirements.

4、 Application of aluminum veneer

Aluminum veneer, as a high-quality and highly reliable building curtain wall material, has a wide range of applications, including public buildings, commercial buildings, residential buildings, sports venues, etc. The use of aluminum veneer can achieve refined and personalized design of building appearance, while also improving the wind pressure resistance and seismic performance of buildings.

Summary:

From the above explanation, we can see that the production process of aluminum veneer is very complex and cumbersome, requiring strict quality management and inspection control. In practical applications, aluminum veneer plays an increasingly important role. It not only improves the aesthetic and fashionable appearance of buildings, but also enhances their safety and fire resistance, making significant contributions to the development of modern architecture.

- previous page:What are the manufacturers of aluminum veneer?

- Next page: No more

Customer service QQ

Customer service QQ