Frequently asked questions

Company News

- Fluorocarbon aluminum veneer: a fashionable weapon in the construction industry, a rising star in aluminum materials

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum alloy air conditioning cover: a perfect combination of fashion and practicality

- The Fantasy Journey of Aluminum Veneer: The Evolution from Materials to Art

- Aluminum veneer, the "silver warrior" of modern architecture

Industry dynamics

- Aluminum veneer: an elegant "coat" in modern architecture

- Can aluminum veneer be applied to the exterior design of retail buildings?

- Fluorocarbon aluminum veneer: the 'invisible hero' of modern architecture

- Is the cleaning requirement for aluminum veneer high?

- Aluminum veneer customization, creating personalized space and new fashion

Frequently asked questions

- What is the wind pressure resistance performance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the value of recycling and reusing aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

- What is the price of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the thickness and specifications of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 23, 2025 18:20:28

- Click:0

Abstract: This article will elaborate in detail on the thickness, specification standards, model selection, and processing technology of aluminum veneer, introducing its application in different fields and providing relevant data and case support.

1、 Thickness

Aluminum veneer is a lightweight and high-strength building decoration material, and its thickness is closely related to its usage. The common thicknesses of aluminum veneer on the market currently include 2mm, 2.5mm, 3mm, 4mm, 5mm and other specifications. Generally speaking, 2mm aluminum veneer is suitable for indoor decoration, such as ceilings, walls, etc; 2.5mm-3mm aluminum veneer is suitable for outdoor curtain walls, ceiling shapes, etc; Aluminum veneer with a thickness of 4mm or more is suitable for large public buildings, high-end commercial venues, and industrial buildings.

In addition, the thickness of aluminum veneer is also influenced by other factors, such as the strength of the aluminum plate, the shape and size of the plate, etc., which can also affect the selection of thickness. Therefore, when choosing the thickness of aluminum veneer, multiple factors need to be considered comprehensively to achieve the best decoration and usage effect.

The thickness of aluminum veneer is directly proportional to its weight. Thicker aluminum veneer is relatively heavier and needs to be fully considered in the engineering design and construction process to ensure safety and stability.

2、 Specification standards

The specification standards for aluminum veneer refer to the regulations on the size, shape, and other aspects of aluminum sheets. According to the national standard GB/T 3880.3-2012, the length of aluminum veneer should be between 1000mm-6500mm, the width should be between 1000mm-2000mm, and the thickness of the sheet should comply with the GB/T 5237.1-2008 standard.

In addition, the specifications of aluminum veneer are also affected by factors such as production and processing equipment, and different manufacturers and processing factories may have certain differences. When selecting aluminum veneer, it is necessary to carefully check the product specifications and relevant quality certifications to ensure the effectiveness and safety of use.

3、 Model selection

The selection of aluminum veneer models is based on different purposes and requirements. Normally, the type of aluminum veneer is mainly determined by factors such as the alloy composition and surface treatment method of the aluminum sheet. The commonly used aluminum veneer models include 1060, 3003, 5052, etc. Among them, 1060 aluminum veneer is suitable for indoor decoration, display cabinets, etc; 3003 aluminum veneer is suitable for decorative materials, kitchen supplies, etc; 5052 aluminum veneer is suitable for building curtain walls, large industrial equipment, etc.

Aluminum veneers of different models have different physical and chemical properties. Therefore, when selecting a model, comprehensive consideration should be given to factors such as usage scenarios and environmental conditions to ensure that the product meets the requirements and has strong durability.

4、 Processing technology

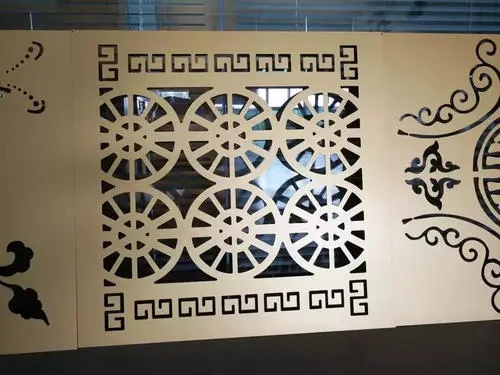

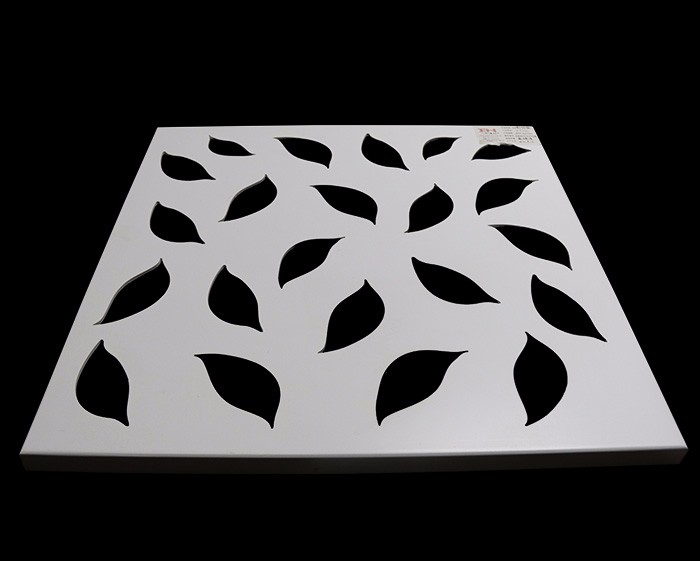

Aluminum veneer requires various processing and treatment techniques during the manufacturing process, including cutting, punching, bending, welding, etc. These processing techniques will have a certain impact on the specifications and dimensions of aluminum veneer, so sufficient consideration and planning are needed in the design and manufacturing process.

At the same time, it is necessary to pay attention to relevant safety issues during the processing, such as workers needing to wear protective equipment and equipment needing to be well maintained, to ensure the safety and reliability of the processing.

5、 Summary

Aluminum veneer, as a high-strength and lightweight building decoration material, has been widely used in the field of modern architecture. Choosing appropriate aluminum veneer thickness, specification standards, and models, as well as conducting scientific and reliable processing techniques, are important factors in ensuring product quality and appearance.

With the continuous advancement of technology and the expansion of application fields, the specifications and application scope of aluminum veneer will also constantly change and update. We look forward to more innovation and development, bringing more beauty and practical value to the building decoration industry.

- Previous Page: None

- Next page:What is the environmental performance of aluminum veneer?

Customer service QQ

Customer service QQ