Corporate News

Company News

- Fluorocarbon aluminum veneer: a choice for light luxury, a new trend in home furnishings

- Fluorocarbon aluminum veneer: the new darling of modern architecture, revealing its charm

- Aluminum alloy air conditioning cover: the guardian of coolness in summer

- Aluminum veneer: the aesthetic secret of modern architecture

- Aluminum air conditioning cover, the guardian of summer coolness!

Industry dynamics

- Unveiling Fluorocarbon Aluminum Veneer: The 'Hidden Champion' in Modern Architecture

- Aluminum alloy air conditioning cover, the cool guardian of summer homes

- How effective is the combination of aluminum veneer and concrete?

- Aluminum veneer: the fashionable "coat" of modern architecture

- What are the application ranges of aluminum veneer?

Frequently asked questions

- What is the wind pressure resistance performance of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What are the manufacturers of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and equipment maintenance of aluminum veneer, measures to improve production efficiency

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-23 12:02:54

- Click:0

Production process and equipment maintenance of aluminum veneer, measures to improve production efficiency

With the continuous development of the construction industry, aluminum veneer, as an emerging building material, is increasingly widely used. However, in order to achieve high-quality and efficient production, it is necessary to scientifically manage and maintain the production process and equipment of aluminum veneer. This article will elaborate on the topic in detail from the following four aspects.

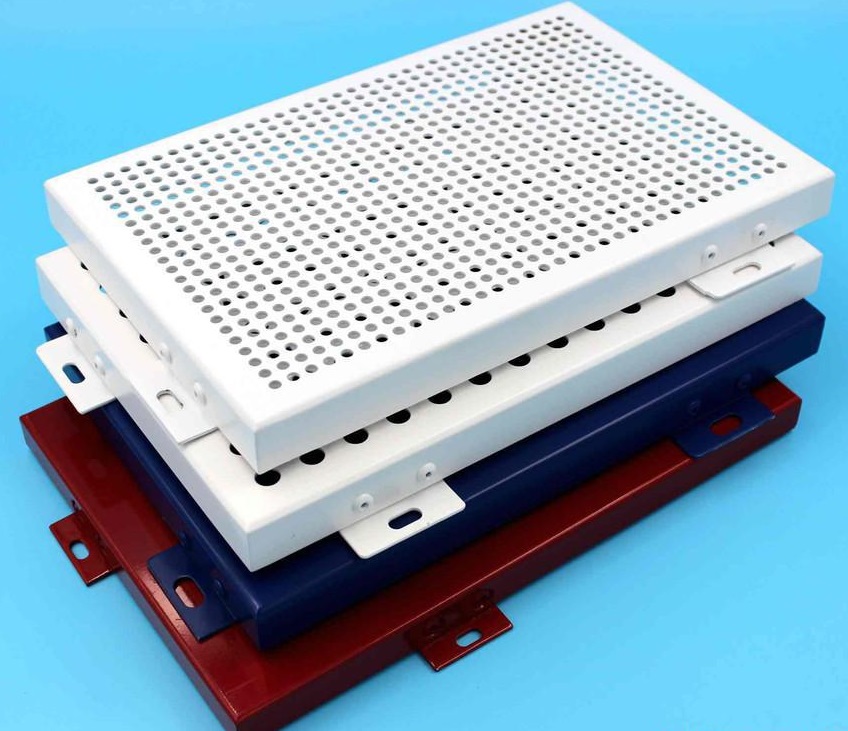

1、 Raw material preparation

The first step in the production of aluminum veneer is the preparation of raw materials, whose quality directly affects the efficiency and quality of subsequent processing steps. Therefore, careful consideration must be given when selecting raw material suppliers. At the same time, in warehouse management, classification, labeling, and moisture-proof treatment should be done well. For different types of aluminum veneer, specialized molds should be used to ensure product accuracy and consistency.

Secondly, raw materials need to undergo strict inspection after being stored, and any defects or defects should be promptly investigated to avoid affecting production progress and finished product quality. During this process, establish a comprehensive record system to facilitate tracking of the source and solution of the problem.

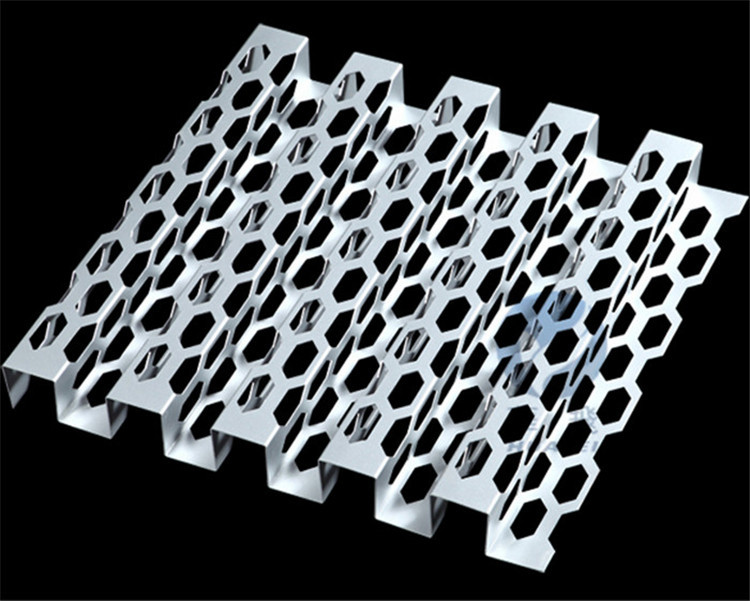

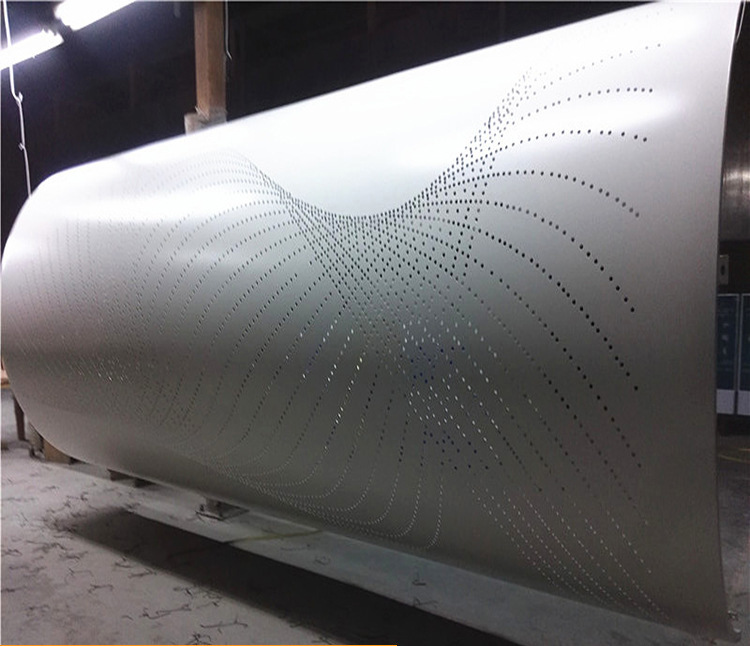

Finally, in the processing of raw materials, it is necessary to strictly control the processing parameters to ensure the accuracy and quality of the product. At the same time, specialized tools and equipment should be used in the process of rendering, punching, and flanging, and necessary maintenance and upkeep should be carried out to extend their service life.

2、 Production process management

The production process of aluminum veneer includes multiple stages such as mold development, sampling, mass production, surface treatment, etc. Each stage requires a clear process flow and strict quality management. In order to improve production efficiency, assembly line and automated production methods can be adopted to standardize operating procedures and reduce human intervention.

In addition, the formulation of production plans is also crucial. A reasonable production plan should be developed based on market demand and customer order information to reduce downtime and waste quantity. When executing the plan, it is necessary to adjust the production schedule and capacity in a timely manner to cope with changing market demand.

At the same time, it is necessary to strengthen employee skills training and safety education, improve their production operations and safety awareness, thereby reducing accident risks and improving work efficiency.

3、 Equipment maintenance management

The equipment used in the production of aluminum veneer is mostly high-precision and high-efficiency machines, which require regular maintenance and upkeep. Firstly, it is necessary to conduct regular inspections and maintenance of the equipment, promptly clean dust and dirt, replace vulnerable parts, to ensure the normal operation of the equipment.

Secondly, it is necessary to strengthen the maintenance management of equipment. Establish a comprehensive maintenance record system, promptly handle faults, prevent the expansion of faults, and reduce production pressure and losses.

Finally, attention should be paid to the energy-saving and environmental protection issues of equipment. Energy consumption and environmental factors should be given priority in equipment selection and use, and new energy-efficient equipment and technologies should be adopted to reduce production costs and achieve sustainable development.

4、 Quality monitoring and improvement

Aluminum veneer is widely used as a building material, and its quality is crucial for the safety and aesthetics of construction projects. Therefore, strict quality monitoring is required for every step in the production process of aluminum veneer.

Firstly, regular product inspections and testing should be conducted. For non-conforming products, the causes should be traced in a timely manner, corrective measures should be formulated to prevent similar problems from happening again. Secondly, it is necessary to establish a comprehensive quality record and feedback mechanism to promptly report any issues discovered during production to the next step, in order to ensure product consistency and stability.

Finally, it is necessary to strengthen continuous improvement and management. Develop improvement plans based on known issues and customer feedback, and track and implement them to continuously improve product quality and competitiveness.

5、 Summary

This article summarizes the production process and equipment maintenance of aluminum veneer, as well as measures to improve production efficiency. Warehouse management, raw material preparation, production process management, equipment maintenance management, and quality monitoring and improvement are important links in the production process of aluminum veneer. Only by maintaining a continuous improvement and optimization attitude in every link can higher quality aluminum veneer products be produced.

Customer service QQ

Customer service QQ