Industry information

Company News

- Aluminum veneer: the beauty of industry, in the details

- Aluminum veneer customization, creating a new proposition for personalized space

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum alloy air conditioning cover: a summer home cooling artifact!

- Aluminum alloy air conditioning cover: the guardian of coolness in summer homes

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Exploring the infinite possibilities of column aluminum veneer in architectural design

- Fashion protection, aluminum alloy air conditioning cover upgrades your home style

- The choice of fluorocarbon aluminum veneer for creating sustainable buildings

- Fluorocarbon aluminum veneer: the fashion "new favorite" in the construction industry

Frequently asked questions

- What is the wind pressure resistance performance of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

- What is the corrosion resistance of aluminum veneer?

- What is the price of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production process and equipment of aluminum veneer, measures to improve production efficiency

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 25, 2025 23:28:54

- Click:0

The production process and equipment of aluminum veneer, measures to improve production efficiency

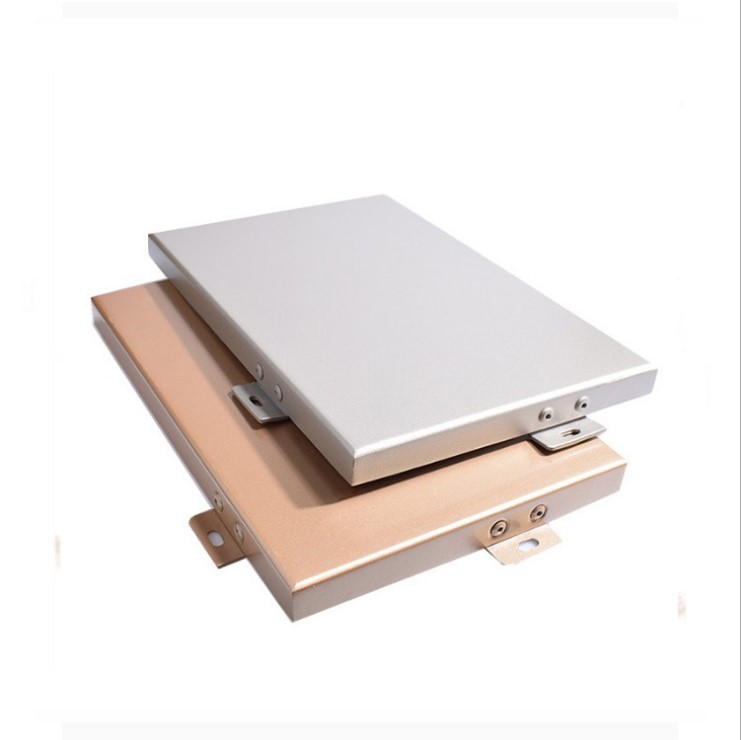

Abstract: Aluminum veneer, as a commonly used building material, has been widely used in modern architecture. This article will start from the production process and equipment of aluminum veneer, and explain how to improve the production efficiency of aluminum veneer through a series of measures.

1、 Raw material selection and processing optimization

1. Raw material selection: The quality and performance of aluminum veneer are directly influenced by the choice of raw materials. In order to improve production efficiency, high-quality aluminum plates should be selected as raw materials and undergo strict quality testing. At the same time, optimize the specifications and thickness of raw materials reasonably to reduce the time and energy consumption of subsequent processing steps.

2. Processing optimization: Processing is a critical step in the production process of aluminum veneer. By optimizing processing techniques and technologies, production efficiency can be improved. For example, introducing advanced CNC cutting equipment and automated production lines can significantly reduce manual operations and processing time, and improve production efficiency. In addition, mold manufacturing and other technological means can be used to improve the forming accuracy and stability of aluminum veneer, further enhancing production efficiency.

3. Waste disposal: During the processing of aluminum veneer, a certain amount of waste and cutting residue will be generated. In order to improve production efficiency, effective treatment and recycling of waste materials should be carried out. By optimizing the disposal of waste materials, resource waste in the production process can be reduced and production efficiency can be improved.

2、 Equipment maintenance and upgrade

1. Equipment maintenance: The production process of aluminum veneer relies on various equipment and mechanical facilities. Regular equipment maintenance is a necessary measure to maintain the normal operation and stability of the equipment. Regularly checking the operating status of equipment, cleaning the surface and internal components of equipment, and timely replacing aging and damaged parts can effectively avoid equipment failures and production delays, and improve production efficiency.

2. Equipment upgrade: With the continuous advancement of technology, new generations of devices and technologies are constantly emerging. In order to improve production efficiency, advanced equipment and technology should be actively adopted. For example, introducing intelligent control systems to achieve automation and intelligent operation of equipment can significantly improve production efficiency. In addition, device upgrades can be used to improve the speed and accuracy of equipment operation, further enhancing production efficiency.

3. Personnel training: The efficient operation of equipment requires operators to possess relevant skills and knowledge. In order to improve production efficiency, emphasis should be placed on personnel training and skill enhancement. Training operators to master equipment operation skills and maintenance knowledge can improve equipment utilization and operational efficiency, thereby enhancing the production efficiency of aluminum veneer.

3、 Process optimization and management improvement

1. Process optimization: The production process of aluminum veneer involves multiple processes and links. By optimizing the process flow, unnecessary links and procedures in the production process can be reduced, further improving production efficiency. For example, reasonable planning and arrangement of production sequence, making good use of time and space between various processes, can effectively reduce waiting and adjustment time, and improve production efficiency.

2. Automated control: Introducing an automated control system is key to improving production efficiency in the production process of aluminum veneer. The automation control system can monitor and control various parameters and indicators in the production process in real time, achieve refined and intelligent production management, and improve production efficiency. Through automation control, human interference and misoperation can be reduced, and the stability and consistency of the production process can be improved.

3. Management improvement: Effective management is the guarantee for improving production efficiency. Establishing a scientific and reasonable production planning and scheduling management system, allocating resources and manpower reasonably, strictly controlling the quality and time requirements in the production process, can timely discover and solve problems, and improve production efficiency. In addition, attention should be paid to employee participation and communication, stimulating their enthusiasm and creativity, and improving team collaboration efficiency.

4、 Technology research and innovation application

1. Technological research and development: In order to improve the production efficiency of aluminum veneer, efforts should be made to increase technological research and development. By continuously researching and developing new technologies and processes, the production process and equipment of aluminum veneer can be optimized, and production efficiency can be improved. For example, developing new coating and surface treatment technologies can reduce the time and energy consumption of the coating process, and improve the quality and efficiency of the coating.

2. Innovative application: As a building material, the application field of aluminum veneer is constantly expanding. In order to improve production efficiency, we should actively explore new application areas and market demands. For example, applying aluminum veneer to the fields of interior decoration and furniture manufacturing can expand the sales market of products and improve production efficiency. At the same time, attention should also be paid to product functional innovation and performance improvement to meet the needs of different users.

5、 Summary:

Through measures such as raw material selection and processing optimization, equipment maintenance and upgrading, process optimization and management improvement, as well as technology research and innovative application, the production efficiency of aluminum veneer can be effectively improved. In the future production of aluminum veneer, we should continue to pay attention to technological innovation and management improvement, continuously improve production efficiency, and promote the healthy development of the aluminum veneer industry.

Customer service QQ

Customer service QQ