Frequently asked questions

Company News

- Aluminum alloy air conditioning cover: cool in summer, guarding the beauty of home

- Aluminum veneer: The beauty of architecture lies within this single piece of aluminum material

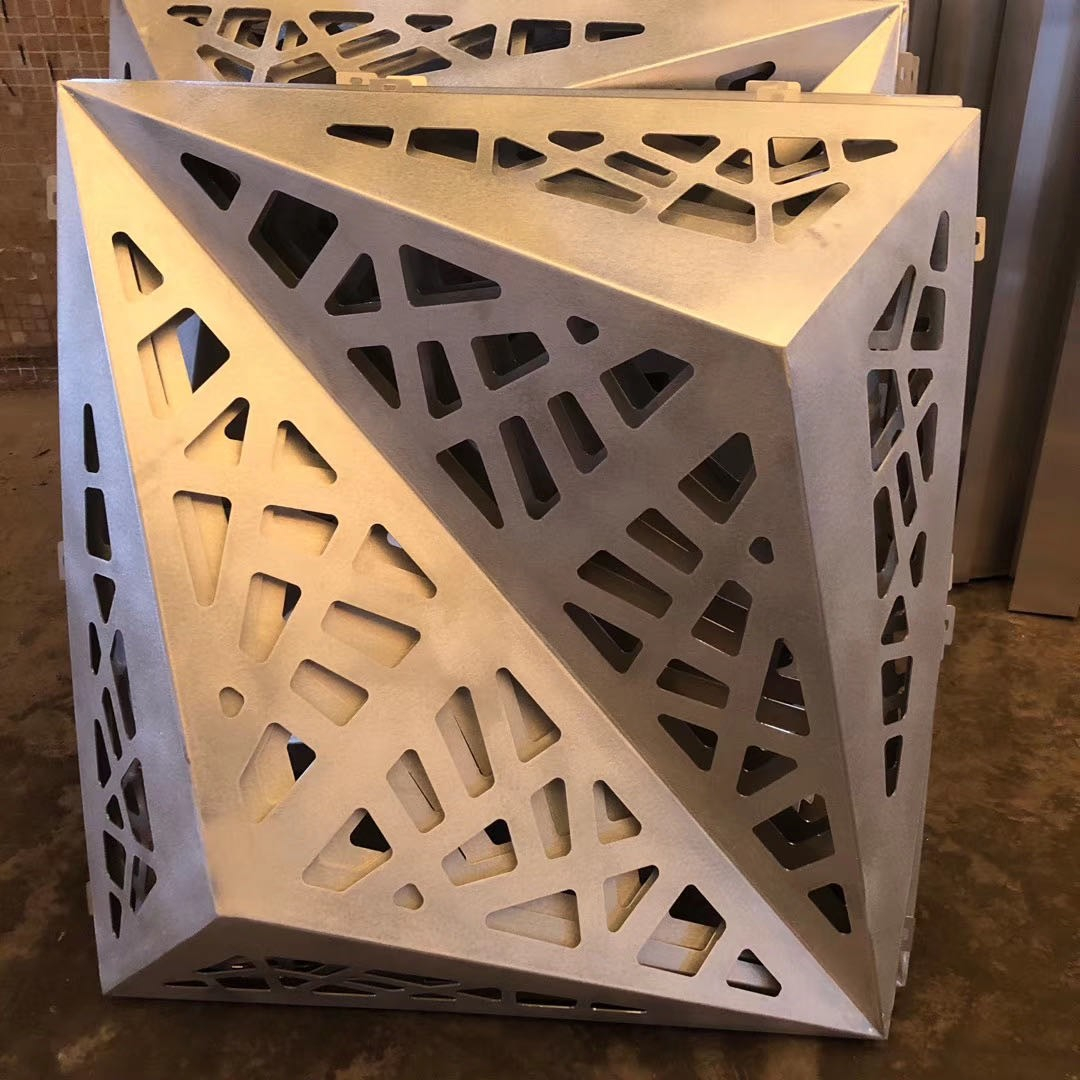

- The charm of aluminum veneer: it's not just about building materials

- The magnificent transformation of aluminum veneer: the new darling of modern architecture

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

Industry dynamics

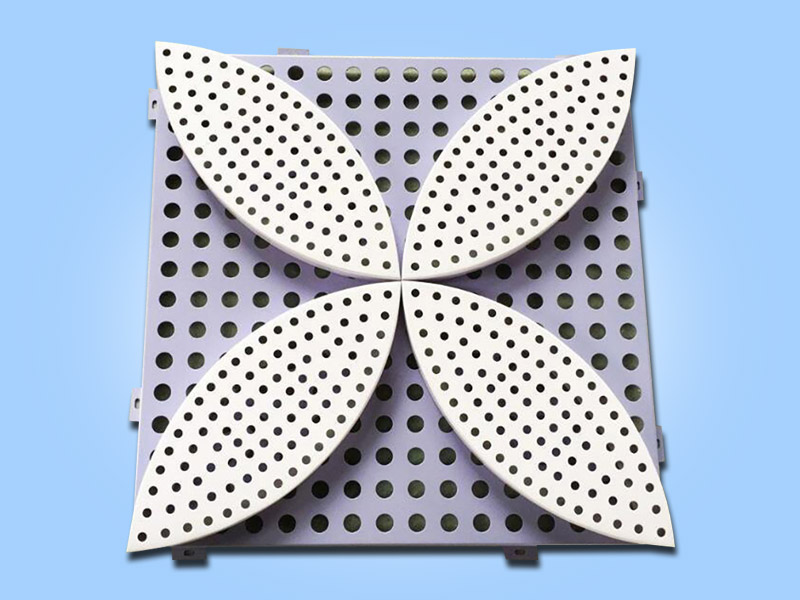

- Personalized customized architectural perforated aluminum veneer showcases unique artistic charm

- Fluorocarbon aluminum veneer: the 'invisible hero' of modern architecture

- Is the surface treatment of aluminum veneer durable?

- Aluminum veneer customization, creating personalized space and new fashion

- Strength testing and result interpretation of carved aluminum veneer

Frequently asked questions

- What are the manufacturers of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

- What is the price of aluminum veneer?

- What is the production process of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

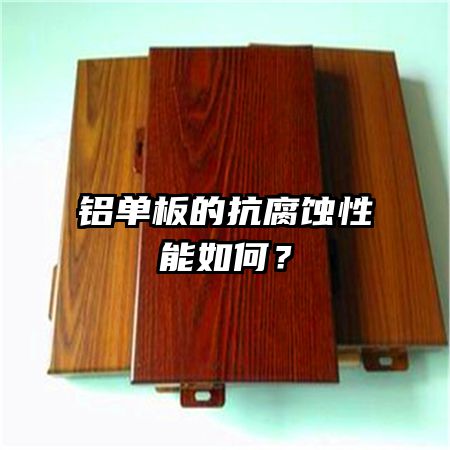

What is the corrosion resistance of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 24, 2025 03:38:11

- Click:0

What is the corrosion resistance of aluminum veneer?

Abstract: This article will elaborate on the corrosion resistance of aluminum veneer from four aspects. Firstly, introduce the corrosion resistance characteristics of aluminum veneer, and then explore its corrosion resistance performance in different environments. Next, analyze the effect of surface treatment on the corrosion resistance of aluminum veneer and cite the research of other experts. Finally, summarize the corrosion resistance performance of aluminum veneer and look forward to its future development trends.1、 Corrosion resistance characteristics

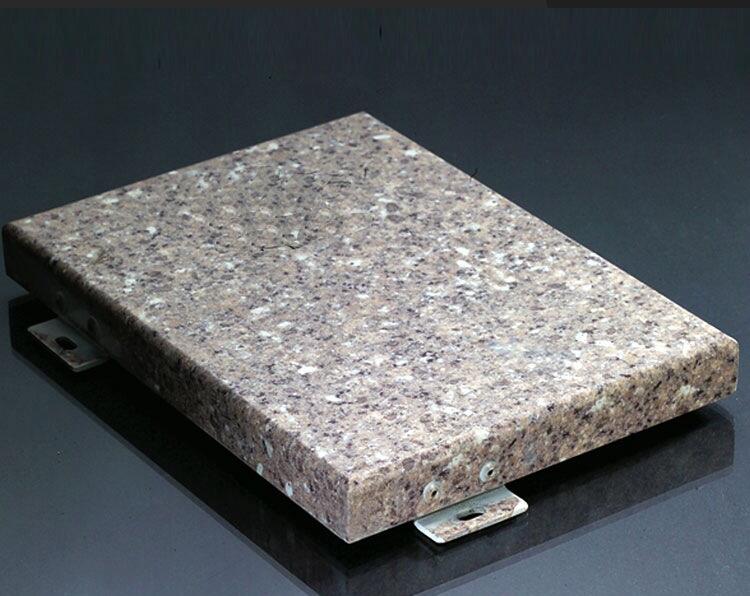

Aluminum veneer, as a lightweight metal material, has excellent corrosion resistance. Firstly, aluminum has the ability to self repair, which means that when its surface is damaged, a dense oxide film will form to prevent further corrosion. In addition, aluminum veneer also has low electrochemical reactivity and exhibits good corrosion resistance in most acidic and alkaline environments.

Secondly, in common atmospheric environments, aluminum veneer can effectively resist corrosive substances such as oxygen, water, and sulfur dioxide in the atmosphere. This is because the oxide film formed on the surface of aluminum veneer can provide a certain protective layer to prevent corrosive substances from penetrating into the inner metal layer.

In addition, aluminum veneer also has the ability to resist marine salt spray corrosion. Years of practice have proven that aluminum veneer exhibits strong corrosion resistance in coastal areas or environments rich in chloride ions in the atmosphere, and can resist erosion caused by ocean salt spray.

2、 Corrosion resistance in different environments

The corrosion resistance of aluminum veneer varies slightly in different environments. Firstly, in acidic environments, aluminum veneers may be subject to a certain degree of corrosion. Hydrogen ions in acidic environments can damage the oxide film on the surface of aluminum, leading to increased corrosion. However, in general, aluminum veneer can also maintain good corrosion resistance in acidic environments.

Secondly, in alkaline environments, the corrosion resistance of aluminum veneer is relatively good. Hydroxyl ions in alkaline environments can form stable hydroxide aluminum complexes with aluminum surfaces, further enhancing their corrosion resistance.

In addition, aluminum veneer can also maintain good corrosion resistance in high temperature environments. Under high temperature conditions, the oxide layer on the surface of aluminum will form more rapidly and become denser, effectively resisting the erosion of external corrosive substances.

3、 The Effect of Surface Treatment on Anti Corrosion Performance

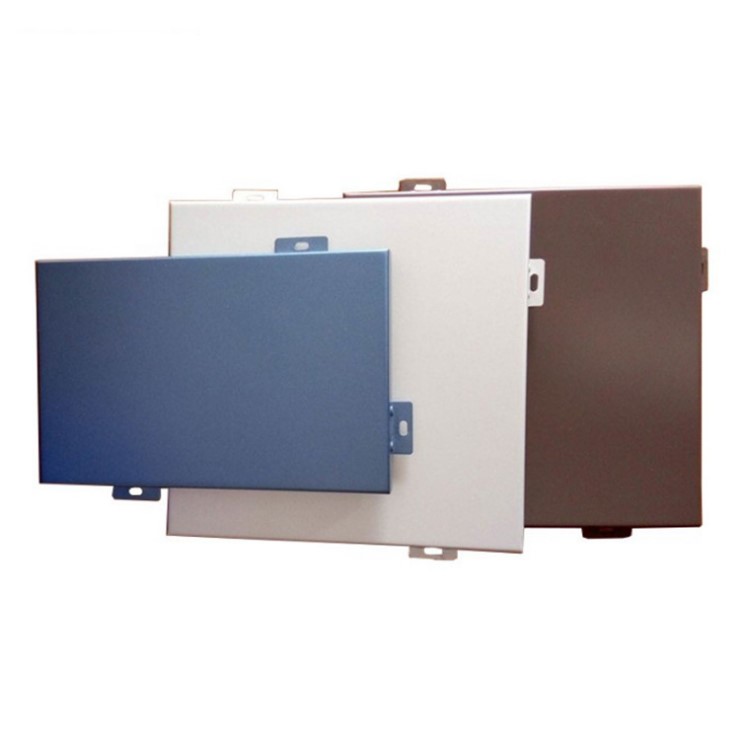

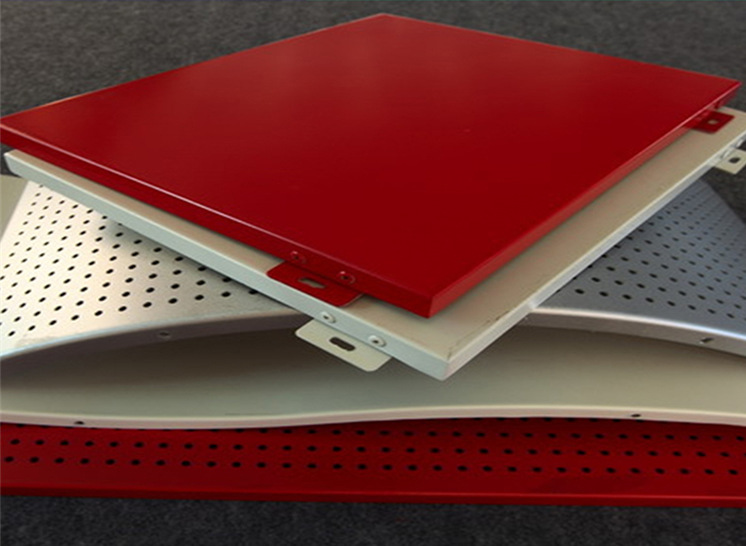

The surface treatment of aluminum veneer has a significant impact on its corrosion resistance. Common surface treatment methods include anodizing and spraying.

Anodizing is the process of generating a dense oxide layer on the surface of aluminum using the principle of electrolysis. This oxide layer has the advantages of high hardness, wear resistance, and corrosion resistance, which can effectively improve the corrosion resistance of aluminum veneer.

Another common surface treatment method is spraying. By spraying different coating materials, the corrosion resistance of aluminum veneer can be increased. For example, polyester powder coating can form a dense protective film, improving the corrosion resistance of aluminum veneer.

4、 Summary

Aluminum veneer, as a lightweight metal material, has excellent corrosion resistance. Its corrosion resistance features include automatic repair ability, resistance to atmospheric corrosion and marine salt spray corrosion, etc. Meanwhile, the corrosion resistance performance varies slightly in different environments, but overall it performs well. Surface treatment methods such as anodizing and spraying play an important role in improving the corrosion resistance of aluminum veneer. In the future, with the development of technology and the improvement of processes, the corrosion resistance of aluminum veneer will be further enhanced.

Customer service QQ

Customer service QQ