Industry information

Company News

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum alloy air conditioning cover: cool summer, new fashion for home!

- Aluminum alloy air conditioning cover: elegant home style, one cover determines the universe

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

Industry dynamics

- What is the applicability of curtain wall aluminum veneer in different climates?

- Exploring the multifunctional application areas of aluminum veneer

- Aluminum alloy air conditioning cover: the guardian of coolness in summer

- Environmental characteristics of stone patterned aluminum veneer

- Selected aluminum veneer customization showcases extraordinary quality

Frequently asked questions

- What are the manufacturers of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

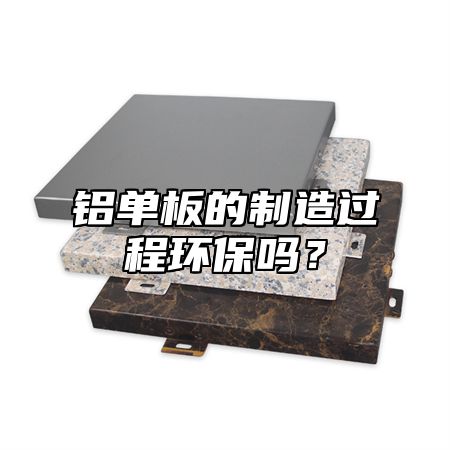

Is the manufacturing process of aluminum veneer environmentally friendly?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 17, 2025 10:43:52

- Click:0

As a common building material, whether the manufacturing process of aluminum veneer is environmentally friendly is one of the important considerations for customers when choosing to use this product. This article will provide a detailed introduction to the manufacturing process of aluminum veneer and analyze its environmental performance.

1、 Raw material procurement

The main raw material for aluminum veneer is aluminum alloy sheet, and the production process of aluminum alloy sheet generates a large amount of pollutants such as carbon dioxide emissions and wastewater. When purchasing raw materials, companies need to choose suppliers that meet environmental standards to reduce their impact on the environment. Enterprises can also adopt the method of recycling and reusing to reduce the waste of raw materials.

2、 Production process

The production process of aluminum veneer mainly includes melting, rolling, surface treatment and other stages. In these processes, a large amount of pollutants such as wastewater, exhaust gas, and solid waste may be generated. In order to reduce the impact on the environment, enterprises need to take a series of environmental protection measures, such as adopting low pollution production processes, strengthening the treatment and recycling of wastewater and exhaust gas, etc.

3、 Surface treatment

The surface treatment of aluminum veneer usually includes methods such as anodizing, electrophoretic coating, powder coating, etc. These methods may generate some harmful substances during the production process, such as organic solvents, heavy metals, etc. In order to ensure the environmental performance of aluminum veneer, enterprises need to choose surface treatment agents and equipment that meet environmental standards, and strengthen the treatment and recycling of exhaust gas and wastewater.

4、 Recycling of waste aluminum veneer

Aluminum veneers will produce some waste aluminum veneers during use. If these waste aluminum veneers cannot be effectively recycled and utilized, they will cause certain pollution to the environment. Enterprises need to establish a comprehensive recycling system for waste aluminum veneers, which includes sorting, cleaning, processing, and other treatments to achieve resource recycling.

The manufacturing process of aluminum veneer has certain environmental impacts, but by adopting a series of environmental protection measures, the impact on the environment can be reduced and the environmental performance of aluminum veneer can be improved. Enterprises need to pay attention to product quality and service level, and actively respond to national environmental policies and requirements, making their own contributions to protecting the environment.

Customer service QQ

Customer service QQ