Corporate News

Company News

- Aluminum air conditioning cover: Guardian of coolness in summer

- Aluminum veneer: a light luxury element in modern architecture

- Fluorocarbon aluminum veneer: an innovative material for architectural aesthetics

- Aluminum veneer: the green guardian of modern architecture

- Aluminum alloy air conditioning cover: the secret weapon to protect the coolness of summer

Industry dynamics

- Fluorocarbon aluminum veneer: creating a new style of modern architecture

- Fluorocarbon aluminum veneer: the 'invisible hero' of modern architecture

- Material selection and environmental characteristics analysis of 3mm aluminum veneer for curtain wall

- Aluminum alloy air conditioning cover: Guardian of summer coolness

- What is the machinability of fluorocarbon aluminum veneer?

Frequently asked questions

- What are the manufacturers of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

- What is the price of aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

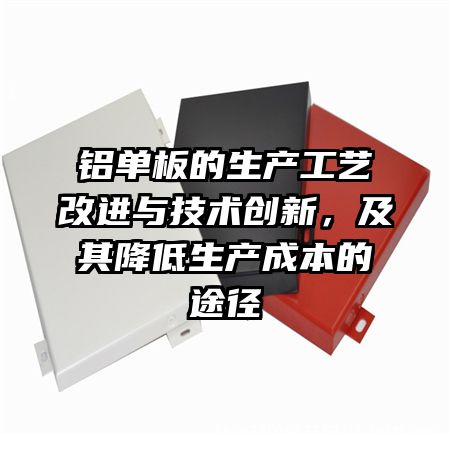

Improvement of production process and technological innovation of aluminum veneer, and ways to reduce production costs

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 22, 2025 21:12:23

- Click:0

Improvement of production process and technological innovation of aluminum veneer, and ways to reduce production costs

With the development of the construction industry, aluminum veneer is increasingly favored by people. However, the high production cost and long production cycle of aluminum veneer limit its further application. Therefore, this article will explore the production process improvement and technological innovation of aluminum veneer from the following four aspects, as well as ways to reduce production costs.

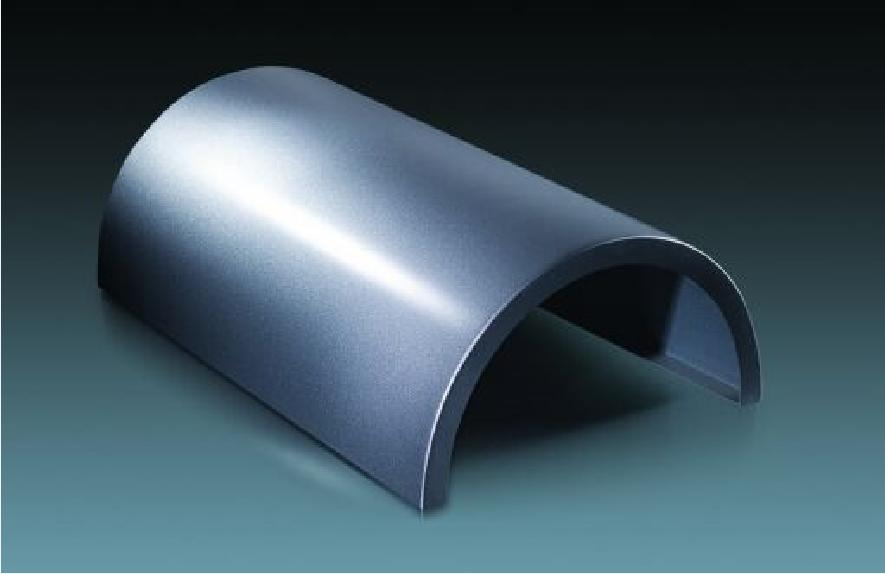

1、 Material selection and optimization

The choice of materials directly determines the cost and quality of aluminum veneer. In terms of material selection, alloy aluminum plates with relatively low prices can be prioritized as substrates, while optimizing material thickness, strength, corrosion resistance, and other aspects to improve material utilization and durability.

In addition, the surface of aluminum veneer can be coated and textured according to application scenarios to achieve anti fouling, anti-corrosion, and aesthetic effects, while reducing subsequent maintenance costs and cycles.

2、 Equipment improvement and automation

The accuracy and efficiency of the equipment have a significant impact on the production efficiency and cost of aluminum veneer. Therefore, by improving the equipment, enhancing its automation level and production accuracy, the goal of mass production and reducing labor costs can be achieved.

For example, using more advanced cutting, bending, welding and other equipment to improve the efficiency and quality of the production line; Applying intelligent control systems to achieve automatic machine processing can not only ensure product consistency and stability, but also reduce labor costs.

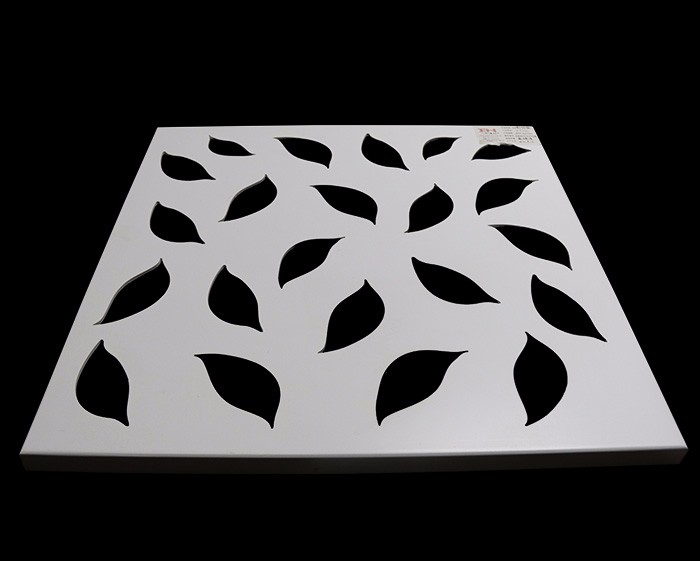

3、 Process improvement and optimization

The improvement and optimization of processes can enhance the production efficiency and quality of aluminum veneer, while reducing waste and losses during the production process. For example, in the painting process, electrostatic spraying or assembly line spraying technology can be used to optimize the painting process, improve the uniformity and efficiency of spraying.

In addition, more advanced TIG argon gas shielded welding technology can be used in the welding process to improve welding quality and efficiency, reduce scrap rates and labor costs.

4、 Green environmental protection and resource conservation

Green environmental protection and resource conservation are important tasks in current society. Aluminum veneer, as a high-end building material, should be considered from the perspectives of green environmental protection and resource conservation.

For example, when using aluminum veneer, biodegradable plastic packaging can be used instead of traditional plastic film packaging to reduce plastic pollution; In the production process, technologies such as circulating water systems and waste recycling can be used to achieve the conservation and reuse of water resources and energy.

5、 Summary

Through the exploration of process improvement and technological innovation in aluminum veneer production, we can find that material selection and optimization, equipment improvement and automation, process improvement and optimization, green environmental protection and resource conservation are key ways to reduce the production cost of aluminum veneer. In the future, with the continuous innovation and progress of technology, the production process and technology of aluminum veneer will be further improved and enhanced, and the quality and cost-effectiveness of aluminum veneer products will be more superior.

Customer service QQ

Customer service QQ