Corporate News

Company News

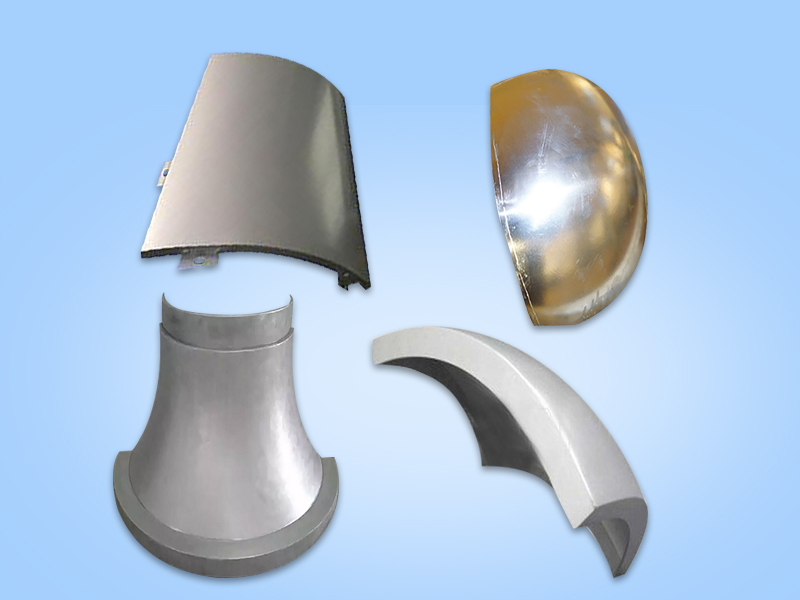

- Customized aluminum veneer, creating a new trend of personalized space

- Aluminum veneer: a perfect fusion of lightness and aesthetics

- Customize aluminum veneer to create a new trend of personalized space!

- How much do you know about aluminum veneer: a fashionable element in architecture?

- Aluminum alloy air conditioning cover: the guardian of coolness in summer

Industry dynamics

- Aluminum alloy air conditioning cover: the "guardian of coolness" for fashionable homes

- Green and environmentally friendly aluminum veneer creates a healthy suspended ceiling

- The perfect combination of carving art and curtain wall aluminum veneer

- Fluorocarbon aluminum veneer: the 'invisible hero' of modern architecture

- Creative painted carved aluminum veneer showcases the beauty of art

Frequently asked questions

- What are the manufacturers of aluminum veneer and how to choose?

- What are the manufacturers of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What is the value of recycling and reusing aluminum veneer?

- What is the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Improvement of production process and technological innovation of aluminum veneer, ways to reduce production costs

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 24, 2025 02:57:22

- Click:0

1、 Optimization of Material Selection and Design

The selection of materials and optimization of design in the production process of aluminum veneer are of great significance for reducing production costs. Firstly, high-quality and stable performance aluminum alloys should be selected as raw materials to ensure the stability of product quality. Secondly, the thickness and pattern of the board should be optimized to reduce the usage of aluminum veneer and achieve the goal of reducing production costs.

In the production of aluminum veneer, the use of high-quality aluminum alloy materials can improve the durability of the product and reduce maintenance and replacement costs. Optimizing sheet design can reduce the use of aluminum veneer, lower production costs, and make products more aesthetically pleasing and practical.

For material selection and design optimization, it is necessary to continuously improve and innovate through market research and technological development, combined with actual needs and customer feedback.

2、 Improvement and Upgrade of Production Process

Improving and upgrading the production process of aluminum veneer is one of the important ways to reduce production costs. Firstly, the production process should be optimized by adopting advanced production equipment and technology to improve production efficiency and automation level. Secondly, quality management and process control should be strengthened to reduce waste rates and production costs.

In terms of production technology, adopting new technologies and equipment can reduce production costs, improve product quality and production efficiency. At the same time, strict quality control and process management can reduce waste and defective product rates, lower production costs, and enhance product competitiveness.

For the improvement and upgrading of production processes, it is necessary to combine market demand and technological research and development, continuously improve and innovate through practice and exploration, in order to meet customer needs and maintain industry competitiveness.

3、 Green and environmentally friendly production

Green and environmentally friendly production is an increasingly important topic in the production process of aluminum veneer. Adopting green and environmentally friendly production processes and materials can reduce production costs, improve product competitiveness, meet customer needs, and protect the environment.

In the production process, renewable energy and low-carbon emission technologies should be adopted to reduce pollution and impact on the environment. At the same time, environmentally friendly materials and technologies should be used to reduce emissions such as wastewater, exhaust gas, and noise, ensuring the green and environmentally friendly production process.

Aluminum veneer enterprises should actively respond to national environmental policies, strengthen environmental awareness, promote the transformation and upgrading of production methods, and achieve sustainable development.

4、 Talent cultivation and technological innovation

Aluminum veneer enterprises need to focus on talent cultivation and technological innovation to enhance their core competitiveness and innovation capabilities. By introducing and cultivating high-quality talents, building a platform for technological innovation, and continuously launching new products and technologies with market competitiveness.

At the same time, aluminum veneer enterprises need to strengthen cooperation with universities, research institutions, etc., carry out technological innovation and industry university research cooperation, and jointly promote the innovation and development of the aluminum veneer industry.

In terms of talent cultivation and technological innovation, aluminum veneer enterprises need to put effort into corporate culture and human resource management, provide a good learning and development environment for talents, and continuously enhance the innovation and competitiveness of the enterprise.

5、 Summary:

Improving the production process and technological innovation of aluminum veneer are important ways to reduce production costs. It is necessary to start from four aspects: optimizing material selection and design, improving and upgrading production processes, green and environmentally friendly production, talent cultivation, and technological innovation. Based on market demand and technological research and development, sustainable development can be achieved through continuous innovation and improvement.

Customer service QQ

Customer service QQ