Corporate News

Company News

- Aluminum veneer: the new darling of modern architecture

- Aluminum veneer, the new darling of the construction industry, reveals its unique charm!

- Aluminum veneer customization, creating a unique spatial aesthetic

- Aluminum veneer customization, creating a new choice for personalized space!

- The charm of aluminum veneer: it's not just about building materials

Industry dynamics

- Aluminum alloy air conditioning cover: the guardian of coolness in summer homes

- Production process and environmental protection of aluminum veneer to reduce environmental pollution

- Understand the installation method of aluminum veneer for engineering ceiling

- Fluorocarbon aluminum veneer: the 'hidden guardian' of fashionable architecture

- An essential 1.5mm thick engineering aluminum veneer for indoor and outdoor building decoration

Frequently asked questions

- What are the manufacturers of aluminum veneer and how to choose?

- How to improve the environmental performance of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What is the price of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and technological progress of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 24, 2025 18:58:13

- Click:0

Production process and technological progress of aluminum veneer

Abstract: With the continuous development of technology, the production process and technology of aluminum veneer are also constantly improving. This article will elaborate on the production process and technological progress of aluminum veneer from four aspects: material selection, processing technology, surface treatment, and quality control.

1、 Material selection

1. Application of New Aluminum Alloy Materials

With the development of science and technology, new aluminum alloy materials with higher strength and better corrosion resistance are widely used in the production of aluminum veneer. These new materials can provide better mechanical properties and weather resistance, enabling aluminum veneer to maintain stable and excellent performance in various environments.

2. Selection of environmentally friendly materials

Against the backdrop of increasing environmental awareness, more and more environmentally friendly materials are being used in the production of aluminum veneer. These materials are non-toxic, pollution-free, meet environmental requirements, and can reduce the consumption of natural resources, reducing the impact of aluminum veneer production on the environment.

3. Application of customized materials

The trend of using customized materials in aluminum veneer production is becoming increasingly evident to meet the needs of different customers. By selecting materials with different characteristics, various functional requirements and decorative effects of aluminum veneer can be achieved, meeting diverse market demands.

2、 Processing technology

1. Advanced cutting technology

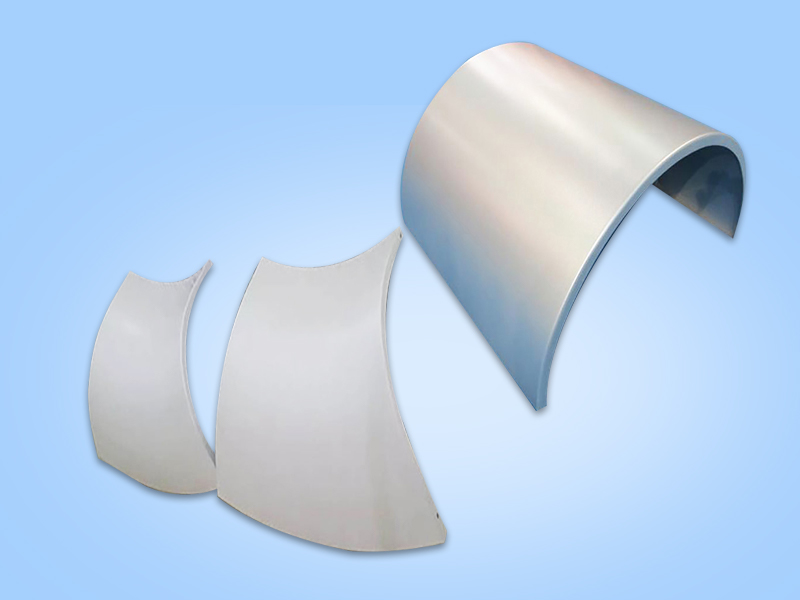

With the application of advanced technologies such as laser cutting and waterjet cutting, the cutting process of aluminum veneer has been greatly improved. These cutting techniques can achieve precise shape and curve cutting, improving the quality and production efficiency of aluminum veneer products.

2. Automated welding technology

Traditional manual welding has problems such as high manual labor and difficulty in ensuring quality, but the application of automated welding technology has solved these problems. Automated welding equipment can achieve efficient and precise welding, improving the welding quality and production efficiency of aluminum veneer products.

3. Intelligent molding technology

The application of intelligent forming technology in the forming process of aluminum veneer makes the product forming more precise and consistent. By controlling and optimizing molding parameters through intelligent devices, deformation and distortion problems caused by inconsistent manual operations can be avoided, improving the appearance quality of aluminum veneer products.

3、 Surface treatment

1. Application of Fluorocarbon Coatings

Fluorocarbon coatings have excellent weather resistance, corrosion resistance, and pollution resistance, and are widely used in surface treatment of aluminum veneers. Fluorocarbon coating can effectively protect the surface of aluminum veneer, extend the service life of products, and there are multiple colors to choose from to meet decoration needs.

2. Improvement of anodizing technology

Anodizing technology is one of the important methods for surface treatment of aluminum veneer. In recent years, with the development and improvement of new electrolytes, anodizing technology has been further enhanced. The improved anodizing technology can achieve a more uniform and detailed oxide film, improving the corrosion resistance and decorative effect of aluminum veneer.

3. Application of Nanotechnology

The application of nanotechnology in surface treatment has promoted the improvement of the surface properties of aluminum veneer. Nano coating can enhance the anti fouling performance and self-cleaning effect of aluminum veneer, keep the product surface clean and bright, and improve the maintenance convenience of aluminum veneer.

4、 Quality control

1. The pre evolution of detection equipment

With the development of technology, various advanced testing equipment are widely used in the production and testing process of aluminum veneer. These devices have the characteristics of high precision, high efficiency, and automation, which can accurately measure and evaluate the size, strength, quality, etc. of aluminum veneer, ensuring product quality.

2. Whole process quality control

The entire process quality control method is adopted in the production of aluminum veneer, from raw material entry, processing and manufacturing to finished product delivery, every link is strictly controlled and standardized. By establishing a scientific quality control system, the situation of overall quality deterioration caused by problems in one link has been avoided.

3. Certification of ISO9001 Quality Management System

More and more aluminum veneer production enterprises have obtained ISO9001 quality management system certification to ensure that their products meet international quality standards and customer needs. The certification of this quality management system can help enterprises establish a scientific and effective quality management mechanism, enhance the quality and competitiveness of aluminum veneer products.

5、 Summary:

With the continuous progress of aluminum veneer production technology and techniques, the quality of aluminum veneer has been significantly improved. The innovation in material selection, improvement in processing technology, advanced surface treatment, and strengthened quality control have all laid a solid foundation for the development of aluminum veneer. In the future, with the continuous innovation of technology, the production process and technological progress of aluminum veneer will continue to drive the development of the industry.

Customer service QQ

Customer service QQ