Corporate News

Company News

- Aluminum Clear Breeze, Home Coolness - The Secret of Aluminum Alloy Air Conditioning Hood

- Aluminum alloy air conditioning cover, summer home cooling guardian

- The charm of aluminum veneer: it's not just about building materials

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer, the new darling of the construction industry, reveals its unique charm!

Industry dynamics

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization: the art of creating personalized spaces

- Aluminum alloy air conditioning cover: Guardian of summer coolness

- Aluminum alloy air conditioning cover: cool home, guarding every comfort you have

- Specification of 1.5mm ceiling aluminum veneer

Frequently asked questions

- What is the corrosion resistance of aluminum veneer?

- What is the price of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

- What is the wind pressure resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and equipment selection of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 23, 2025 15:21:21

- Click:0

Production process and equipment selection of aluminum veneer

Abstract: Aluminum veneer is a widely used material in the field of architectural decoration, which has the characteristics of lightweight, corrosion resistance, and easy processing. The correct selection of production processes and equipment is crucial for improving the quality and production efficiency of aluminum veneer.

1、 Material selection

1. Physical properties of materials: Aluminum veneer materials should have a certain strength and hardness to ensure their stability and durability during installation.

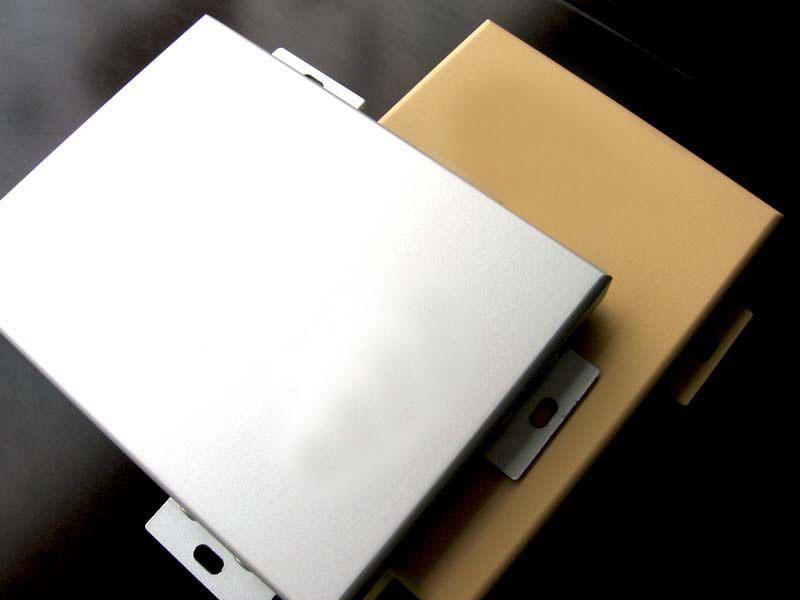

2. Surface treatment of materials: The surface treatment of aluminum veneer can be achieved through spray painting, electrophoretic coating, and other methods to increase its corrosion resistance and aesthetics.

3. Stability of material supply: Select manufacturers or suppliers with stable supply capabilities to ensure uninterrupted material supply during the production process.

2、 Production process

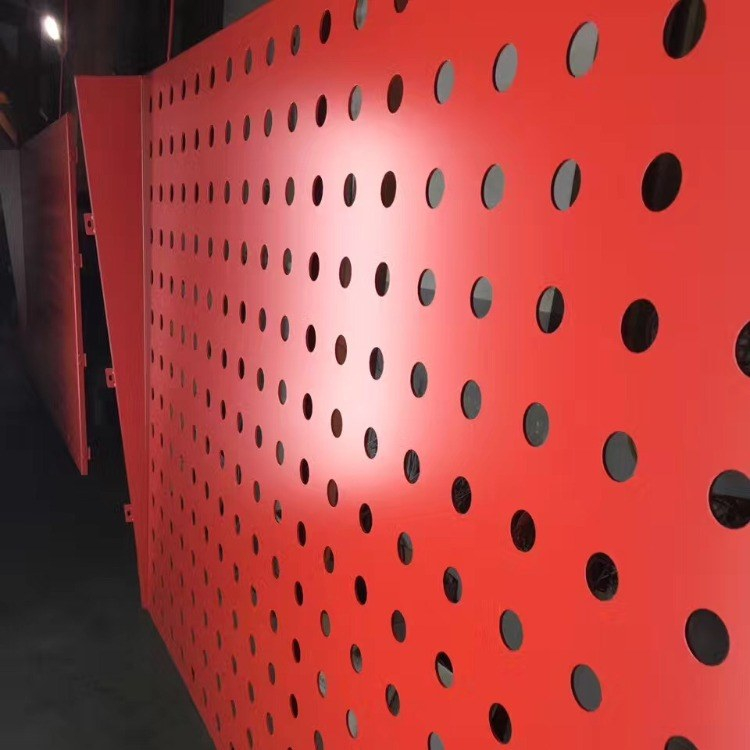

1. Plate cutting: Using a CNC cutting machine for cutting can improve the accuracy and efficiency of the plate.

2. Bending Forming: Using professional bending equipment and molds, the sheet metal is bent and formed according to design requirements to ensure the geometric shape and size of the aluminum veneer.

3. Welding process: Welding of aluminum veneer can be carried out using techniques such as argon arc welding or laser welding to ensure the firmness and aesthetics of the weld seam.

3、 Equipment selection

1. CNC cutting machine: Choosing a CNC cutting machine with stable performance and high precision can improve cutting efficiency and accuracy.

2. Bending equipment: Choosing a CNC bending machine can achieve automated operation, improve production efficiency and product quality.

3. Welding equipment: Select suitable welding equipment according to production needs, such as argon arc welding machine or laser welding machine, to meet the requirements of different welding processes.

4、 Production process control

1. Quality inspection: Conduct strict quality inspections during the production process, including physical property testing of materials, quality assessment of surface treatment, etc., to ensure that the product meets standards.

2. Process parameter control: Reasonable parameter control should be carried out for different process links, such as cutting speed of the cutting machine, bending angle of the bending machine, etc., to ensure product quality and production efficiency.

3. Employee training: Provide relevant training for production processes, enabling employees to proficiently master operating procedures and safety precautions, and improve production efficiency and product quality.

Summary:

The production process and equipment selection of aluminum veneer directly affect product quality and production efficiency. By selecting materials reasonably, adopting scientific production processes, selecting suitable equipment, and implementing strict production process control, high-quality production of aluminum veneer can be achieved to meet the needs of the field of architectural decoration.

Customer service QQ

Customer service QQ