Industry information

Company News

- Customize Your Style - New Proposition for Aluminum Veneer

- Fluorocarbon aluminum veneer: a fashionable outerwear for modern architecture

- Aluminum veneer: a new favorite in the construction industry, what is its charm?

- The Fantasy Journey of Aluminum Veneer: The Evolution from Materials to Art

- Aluminum alloy air conditioning cover: cool in summer, one cover to protect!

Industry dynamics

- Analysis of the production process of aluminum veneer and its advantages in use

- The key to the profitability of aluminum veneer prices and costs

- Aluminum veneer customization, creating a new trend of personalized space

- The perfect combination of stone patterned aluminum veneer texture and durability

- Customized environmentally friendly materials for aluminum veneer lead the new trend of green building

Frequently asked questions

- What is the production process of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What are the manufacturers of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to choose suitable curved ceiling aluminum veneer material

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 20, 2025 03:21:36

- Click:0

Curved ceiling aluminum veneer is a high-end building material, and its material selection needs to be based on the specific requirements of the building. Below, we will provide a detailed introduction on how to choose the appropriate curved ceiling aluminum veneer material.

1、 Material selection of curved ceiling aluminum veneer

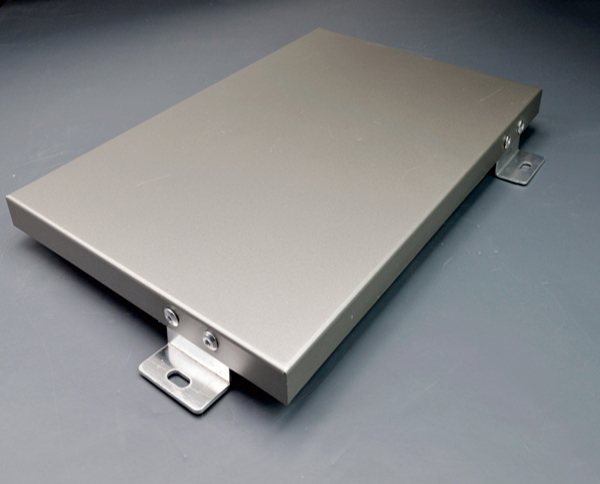

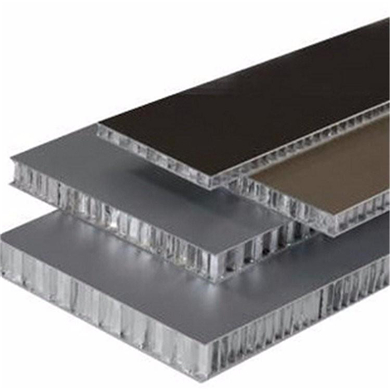

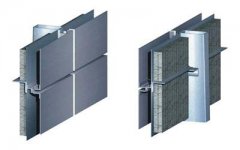

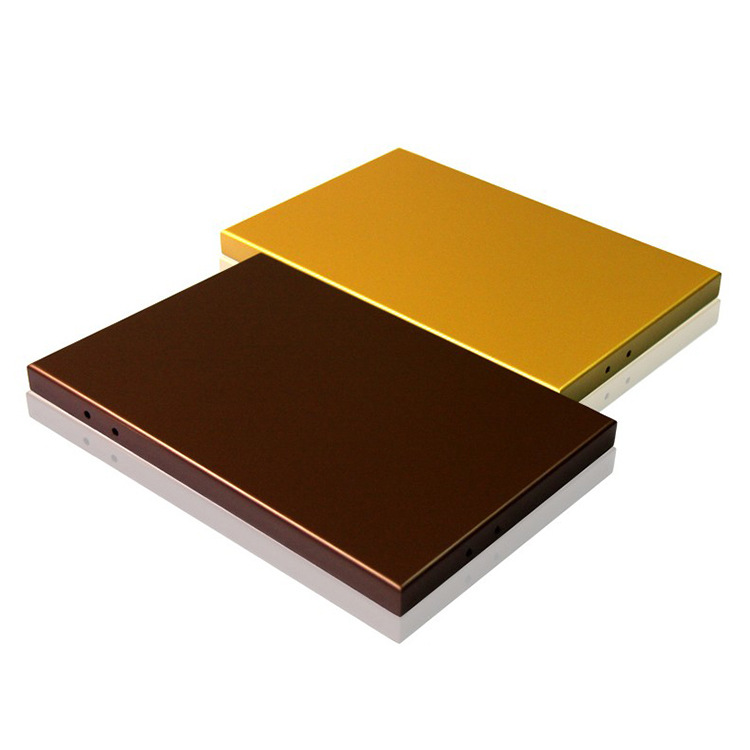

1. Aluminum alloy: Aluminum alloy is one of the main materials for curved ceiling aluminum panels, with advantages such as lightweight and strong corrosion resistance. Aluminum alloys can also undergo surface treatments such as anodizing, spraying, etc. to enhance their aesthetics and durability.

2. Stainless steel: Stainless steel is also one of the commonly used materials for curved ceiling aluminum panels, with advantages such as strong corrosion resistance and high aesthetics. However, compared to aluminum alloy, stainless steel has a higher price.

3. Galvanized sheet: Galvanized sheet is an economical material with advantages such as low price and easy processing. However, the corrosion resistance and aesthetics of galvanized sheet are relatively poor.

2、 Quality selection of curved ceiling aluminum veneer

1. Raw materials: High quality curved ceiling aluminum veneer should be produced using high-quality raw materials to ensure the quality and accuracy of the shape of the aluminum material.

2. Thickness and hardness: The thickness and hardness of the curved ceiling aluminum veneer have a significant impact on the safety and stability of the entire structure, so it is necessary to choose the appropriate thickness and hardness.

3. Surface treatment: The surface treatment of curved ceiling aluminum veneer can enhance its corrosion resistance and aesthetics, so it is necessary to choose high-quality materials that have undergone surface treatment.

3、 Conclusion

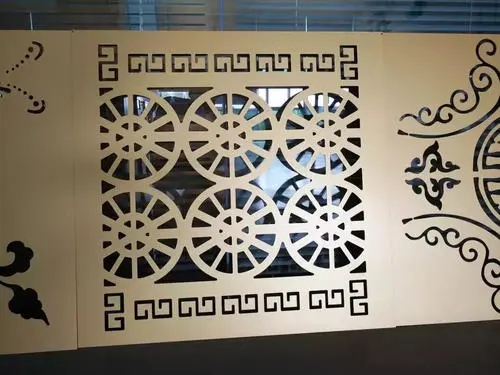

Choosing the appropriate curved ceiling aluminum veneer material requires comprehensive consideration of multiple factors such as the specific requirements of the building, material performance, and quality. In future designs, curved suspended aluminum panels will be more widely used in various buildings, blending with classic elements to make modern architecture more artistic and contemporary.

Customer service QQ

Customer service QQ