Industry information

Company News

- Production process and equipment selection of aluminum veneer

- Fluorocarbon aluminum veneer: the fashion darling of the aluminum industry, revealing its charm!

- Aluminum veneer new trend: not only wall decoration, but also artistic life

- Aluminum veneer: the secret weapon of architectural aesthetics!

- Aluminum alloy air conditioning cover, the new favorite for cool summer home decor!

Industry dynamics

- Quality inspection and selection skills for aluminum veneer

- What is the durability of aluminum veneer?

- Analysis of Sound Insulation Effect of Aluminum Single Panel

- Analysis of the production process of aluminum veneer and its advantages in use

- What color options are available for aluminum veneer?

Frequently asked questions

- What is the wind pressure resistance performance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

- What is the production process of aluminum veneer?

- What are the manufacturers of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of the production process and introduction of process characteristics for hyperbolic 1.5mm aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 23, 2025 14:44:53

- Click:0

Hyperbolic 1.5mm aluminum veneer is a new type of building material, and its manufacturing process is more complex compared to traditional building materials. Below, we will provide a detailed introduction to the manufacturing process and characteristics of hyperbolic 1.5mm aluminum veneer.

1、 Craft production process

The production process of hyperbolic 1.5mm aluminum veneer mainly includes the following steps:

1. Design and drafting

Before producing the hyperbolic 1.5mm aluminum veneer, design and drafting work is required. The designer designs the shape, color, size, and other parameters of the hyperbolic 1.5mm aluminum veneer based on the client's needs and architectural style. Hand over the design drawings to the draftsman for drafting.

2. Material selection and preparation

Before making the hyperbolic 1.5mm aluminum veneer, it is necessary to select and prepare the raw materials. Generally speaking, the main material for hyperbolic 1.5mm aluminum veneer is aluminum alloy, and some auxiliary materials such as sealant and hardware accessories are also required.

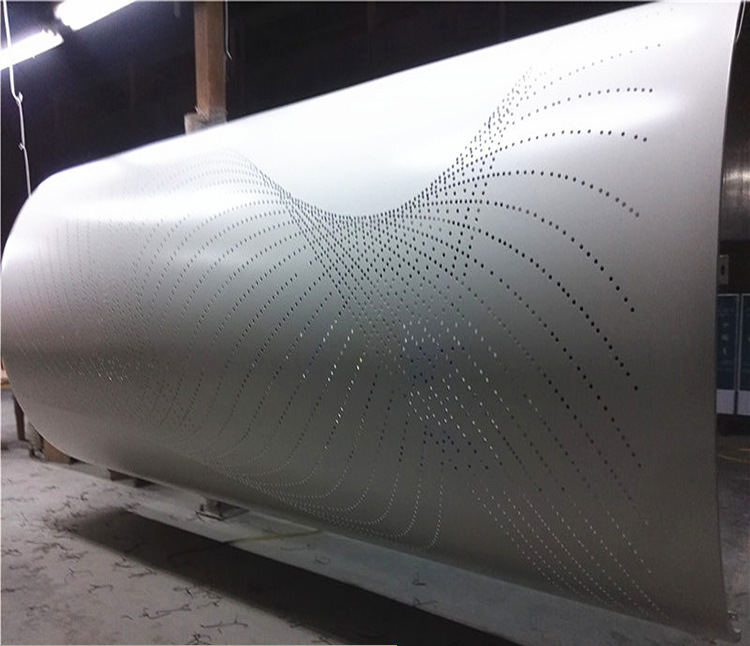

3. Cutting and bending

After completing the design and drawing, it is necessary to cut and bend the raw materials. Generally speaking, cutting and bending are one of the most time-consuming and labor-intensive processes in the entire manufacturing process. In this stage, professional equipment and technology are required to ensure the accuracy and quality of cutting and bending.

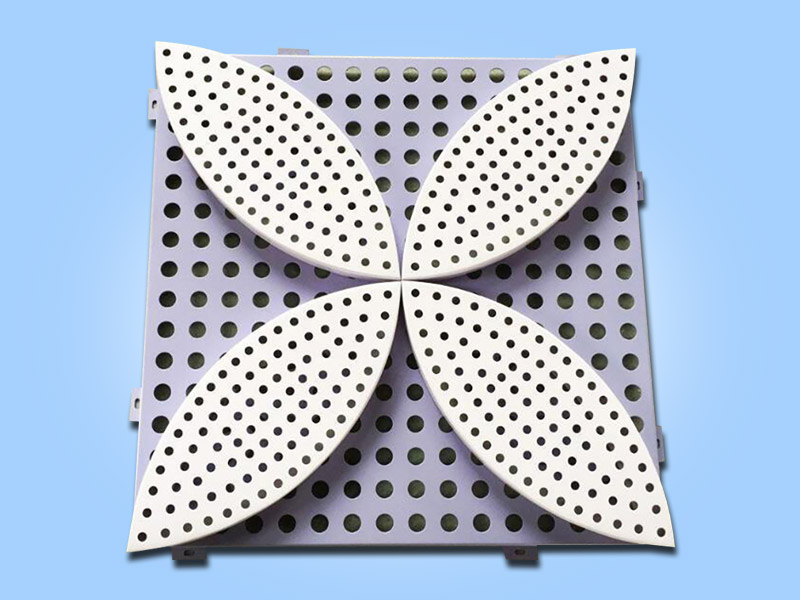

4. Surface treatment

After cutting and bending, it is necessary to perform surface treatment on the hyperbolic 1.5mm aluminum veneer. Generally speaking, surface treatment includes various methods such as spraying, anodizing, electrophoretic coating, etc. These processing methods can increase the oxidation resistance and weather resistance of hyperbolic 1.5mm aluminum veneer, while also improving its surface aesthetics.

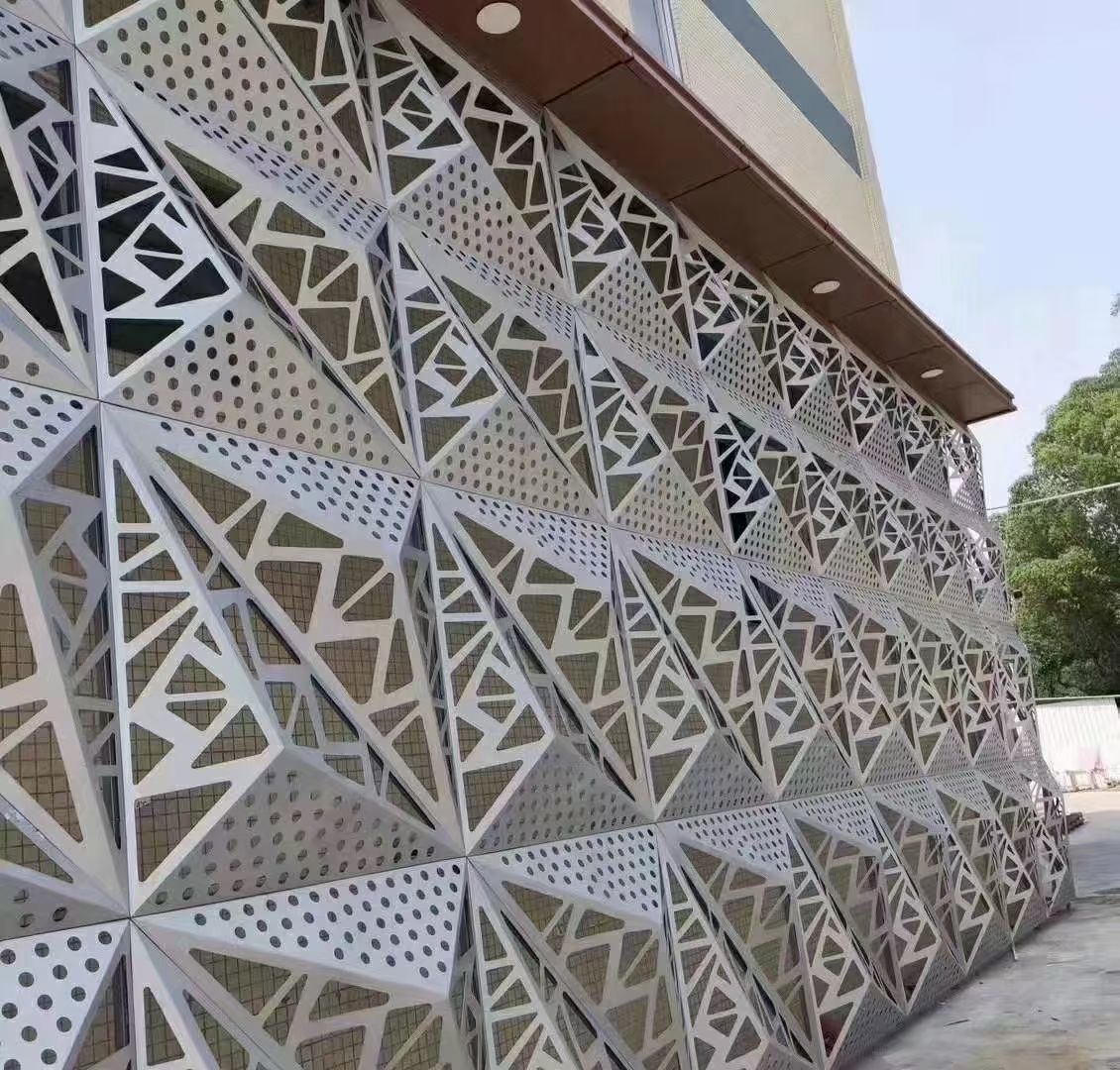

5. Installation and maintenance

After completing the surface treatment, it is necessary to install and maintain the hyperbolic 1.5mm aluminum veneer. The installation process requires the use of professional tools and techniques to ensure the stability and safety of the hyperbolic 1.5mm aluminum veneer. The maintenance process requires regular cleaning and inspection of the surface and structure of the hyperbolic 1.5mm aluminum veneer to ensure its long-term good performance.

2、 Introduction to process characteristics

The process characteristics of hyperbolic 1.5mm aluminum veneer are mainly reflected in the following aspects:

1. High precision

The production process of hyperbolic 1.5mm aluminum veneer requires the use of professional equipment and technology to ensure the accuracy and quality of its cutting and bending. Hyperbolic 1.5mm aluminum veneer has very high precision and accuracy.

2. High intensity

The hyperbolic 1.5mm aluminum veneer is made of high-strength aluminum alloy material, which has very high strength and stiffness. This makes the hyperbolic 1.5mm aluminum veneer have excellent load-bearing capacity and seismic performance.

3. Good corrosion resistance

After surface treatment, the hyperbolic 1.5mm aluminum veneer has excellent oxidation resistance and weather resistance. This allows the hyperbolic 1.5mm aluminum veneer to maintain good performance in various harsh environments for a long time.

4. Beautiful and elegant

Hyperbolic 1.5mm aluminum veneer can be customized according to different design requirements to meet the needs of different architectural styles. Its surface treatment technology can make hyperbolic 1.5mm aluminum veneer have very good aesthetics and decorative properties.

Customer service QQ

Customer service QQ