Industry information

Company News

- Aluminum alloy air conditioning cover: the guardian of summer coolness

- Improvement of production process and technological innovation of aluminum veneer, and ways to reduce production costs

- Fluorocarbon aluminum veneer, the new darling of fashionable building materials!

- Aluminum alloy air conditioning cover: the guardian of summer coolness

- Aluminum veneer: the fashionable choice for modern architecture

Industry dynamics

- Aluminum alloy air conditioning cover: the perfect combination of home fashion and practicality

- Aluminum veneer customization, creating your exclusive fashion space

- Fluorocarbon aluminum veneer: a fashionable choice for modern architecture

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum alloy air conditioning cover: a fashionable "cool" companion for summer homes

Frequently asked questions

- What is the wind pressure resistance performance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What are the manufacturers of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

- What is the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Manufacturing process and workflow of aluminum veneer for curved curtain wall

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-02-25 22:48:10

- Click:0

Arc curtain wall aluminum veneer is a new type of building decoration material, which is widely used in the exterior wall decoration of modern buildings due to its unique design and excellent performance. This article will provide a detailed introduction to the manufacturing process and workflow of aluminum veneer for curved curtain walls.

1、 Manufacturing process of aluminum veneer for curved curtain wall

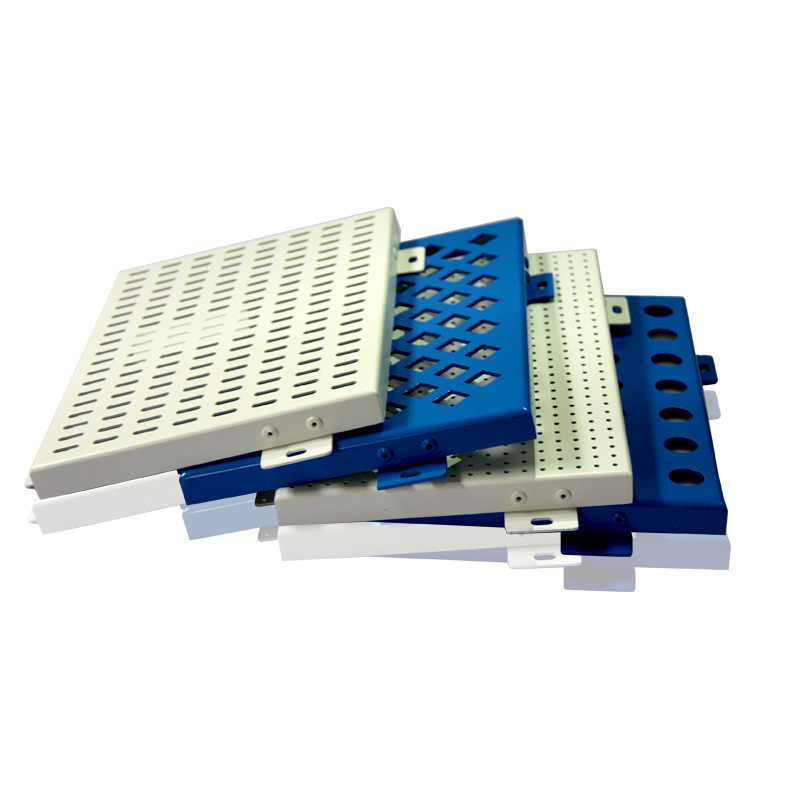

1. Material preparation: The curved curtain wall aluminum veneer mainly uses high-strength aluminum alloy sheets, which require precise measurement and cutting to meet customer needs.

2. Surface treatment: The surface of the curved curtain wall aluminum veneer is specially treated to improve its corrosion resistance and aesthetics. The processing methods include anodizing, spraying, electrophoretic coating, etc.

3. Mold making: According to the customer's design requirements, make corresponding molds for producing curved curtain wall aluminum veneer.

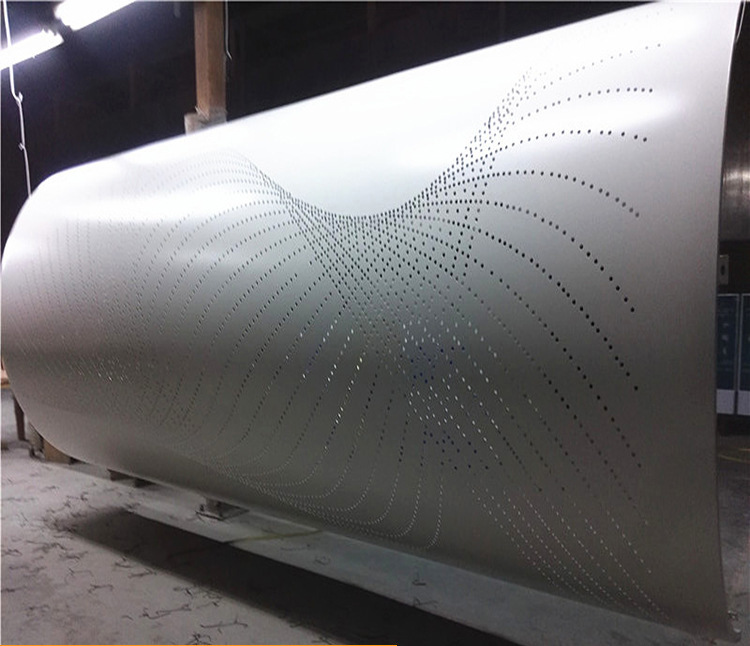

4. Aluminum plate processing: Process the prepared aluminum alloy sheet, including cutting, bending, slotting, etc., to meet the requirements of circular arc shape.

5. Welding assembly: Weld and assemble the processed aluminum plates to form a complete curved curtain wall aluminum veneer.

6. Surface treatment: Surface treatment shall be carried out on the welded arc curtain wall aluminum veneer to improve its corrosion resistance and aesthetics. The processing methods include anodizing, spraying, electrophoretic coating, etc.

2、 Process flow of curved curtain wall aluminum veneer

1. Design phase: Based on the customer's needs and the shape and structure of the building, design and customize the curved curtain wall aluminum veneer.

2. Material preparation: Prepare the required aluminum alloy sheets and other related materials according to the design requirements.

3. Mold making: According to the design requirements, make the corresponding mold.

4. Production and processing: Process the prepared aluminum alloy sheet, including cutting, bending, slotting, etc., to meet the requirements of circular arc shape.

5. Welding assembly: Weld and assemble the processed aluminum plates to form a complete curved curtain wall aluminum veneer.

6. Surface treatment: Surface treatment shall be carried out on the welded arc curtain wall aluminum veneer to improve its corrosion resistance and aesthetics.

7. Packaging inspection: Inspect and package the completed curved curtain wall aluminum veneer to ensure its quality meets the requirements.

3、 Precautions

1. Safety should be taken into account during the production process to avoid accidents.

Before construction, it is necessary to inspect the building materials to ensure that their quality meets the requirements.

During the construction process, it is necessary to pay attention to environmental protection and avoid polluting the surrounding environment.

The production process and flow of aluminum veneer for curved curtain walls are very rigorous, and it is necessary to strictly follow relevant standards for operation. Only in this way can we ensure that its quality meets the requirements and create a better living environment for people.

Customer service QQ

Customer service QQ