Industry information

Company News

- Aluminum Style, Guardian of Summer Air Conditioning

- Aluminum alloy air conditioning cover: Guardian of summer coolness

- Aluminum alloy air conditioning cover: the guardian of summer coolness

- Fluorocarbon aluminum veneer: the new darling of modern architecture, your home upgrade tool!

- Fluorocarbon aluminum veneer: the fashionable new darling of the aluminum industry

Industry dynamics

- Aluminum veneer: the 'hidden hero' of modern architecture

- Aluminum alloy air conditioning cover: a new favorite in home decor and a must-have for cool summer!

- Aluminum alloy air conditioning cover: cool summer, guarding the new fashion of home furnishings

- Aluminum alloy air conditioning cover, a great helper for cool summer!

- Aluminum veneer: the 'invisible hero' of the construction industry

Frequently asked questions

- What is the production process of aluminum veneer?

- What is the value of recycling and reusing aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the price of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production process and cost-benefit analysis of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 24, 2025 06:46:06

- Click:0

Production process and cost-benefit analysis of aluminum veneer

With the development of the economy, the construction industry is also constantly growing. As one of the building materials, aluminum veneer is widely used in the field of building facade decoration due to its lightweight, easy processing, and strong decorative properties. This article will provide a detailed analysis of the production process and cost-effectiveness of aluminum veneer, in order to help readers understand the relevant knowledge of aluminum veneer.

1、 Raw material selection

1. Aluminum plate: The raw material for aluminum veneer is aluminum plate, which generally requires a thickness of 0.5-3mm and a purity of over 90%. Commonly used alloys include 3003, 5005, 5052, etc. The quality of aluminum plates directly affects the forming and aesthetic appearance of aluminum veneers, so manufacturers need to choose high-quality aluminum plates.

2. Coating: Coating is a protective layer on the surface of aluminum veneer, which can prevent damage and corrosion to the surface of aluminum veneer. At present, common coatings on the market include fluorocarbon coatings, polyester coatings, etc. Among them, fluorocarbon coatings have higher quality but relatively higher prices.

3. Other materials: In the production process of aluminum veneer, a series of auxiliary materials and equipment such as fillers, adhesives, and cutting machines are also required.

2、 Production process

1. Pre treatment: Aluminum plates need to undergo surface cleaning, oil removal, oxidation removal and other treatments to ensure the smoothness of the aluminum plate surface and suitability for receiving coatings.

2. Coating treatment: In the coating process, primer, intermediate coat, and topcoat need to be applied, and each layer needs to be dried and modified until the coating quality meets the standards.

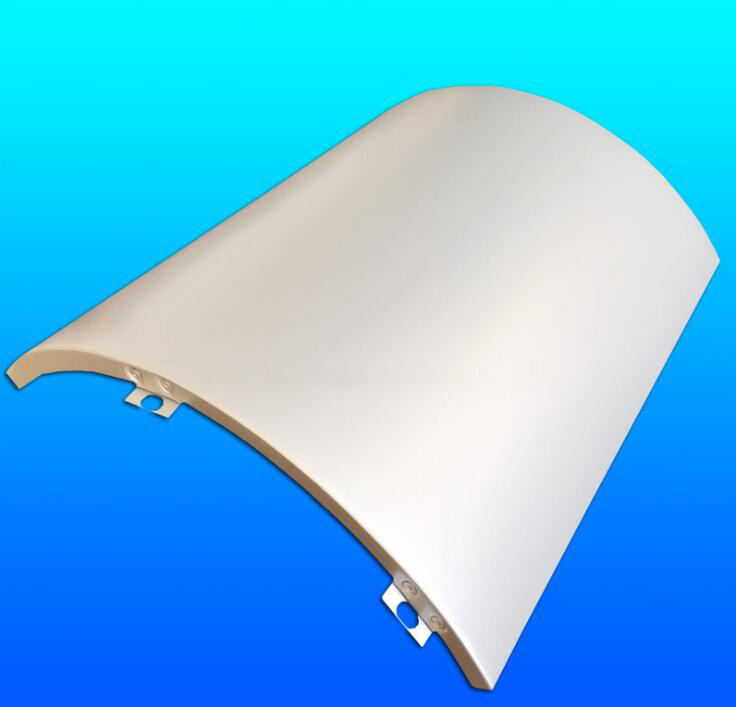

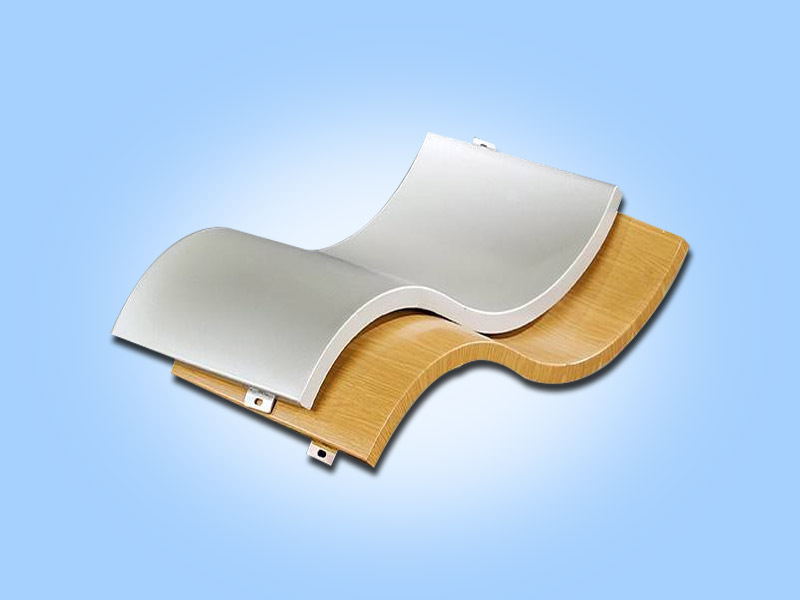

3. Forming: After a series of processes such as cutting, bending, and drilling, aluminum sheets are formed into various shapes of aluminum veneers.

4. Installation: Aluminum veneer will become the decorative material for building facades and needs to be installed.

3、 Cost analysis

1. Raw material cost: The price of aluminum plates is relatively stable, but the price of coatings varies greatly depending on the manufacturer and quality, and other material and equipment costs also need to be considered.

2. Processing cost: The forming of aluminum plates requires professional equipment and technical personnel, so the processing cost is relatively high. At the same time, installation costs also need to be considered.

3. Maintenance cost: Aluminum veneer requires regular maintenance to ensure decorative effect and service life, and maintenance cost also needs to be considered.

4、 Benefit analysis

1. High aesthetic appeal: The surface of aluminum veneer has been coated, with a variety of colors and flexible shapes, which can meet the needs of different building facades and have high aesthetic appeal.

2. Long service life: Aluminum veneer has low density, high strength, excellent corrosion resistance, sound insulation and other properties, with a service life of over 20 years, ensuring the long-term stability of the building.

3. Convenient construction: Aluminum veneer is lightweight, easy to install, and can improve construction efficiency and save construction costs.

5、 Summary

Through the detailed explanation of the production process and cost-effectiveness of aluminum veneer above, it can be seen that aluminum veneer, as an important building decoration material, has high aesthetics and service life. At the same time, attention should be paid to the selection of materials and the control of processing costs during the production process in order to better achieve the goal of maximizing profits.

Customer service QQ

Customer service QQ