Industry information

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: a fashionable outerwear for modern architecture

- Aluminum veneer, a low-key luxury choice in modern architecture

- Aluminum veneer: the fashionable "coat" of modern architecture

Industry dynamics

- The production equipment and technological progress of aluminum veneer, as well as the development trend of automation production

- Aluminum alloy air conditioning cover: a fashionable "cool" companion for summer homes

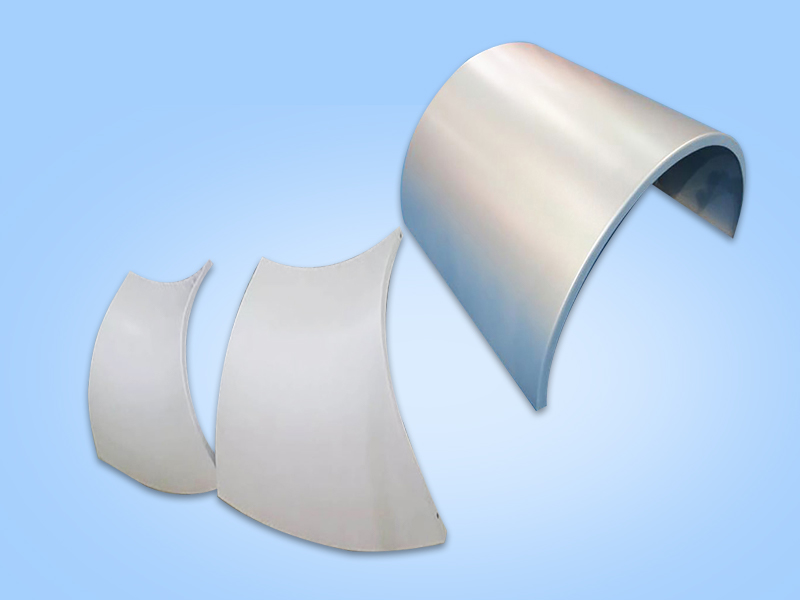

- Reinforced and durable curved exterior aluminum veneer products

- Aluminum veneer, the fashionable outerwear of architecture

- Aluminum alloy air conditioning cover: a new favorite in home decor and a must-have for cool summer!

Frequently asked questions

- What is the value of recycling and reusing aluminum veneer?

- What is the price of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

- What are the thickness and specifications of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Impact resistance test of 1.5mm aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-08 16:10:39

- Click:0

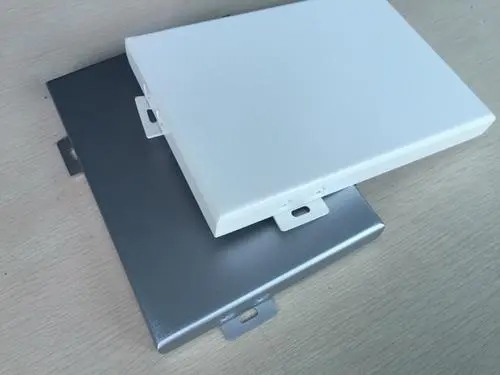

1.5mm aluminum veneer is a very common building material, and its impact resistance is of great significance for ensuring the safety and durability of buildings. This article will provide a detailed introduction to the impact resistance testing of 1.5mm aluminum veneer.

In terms of material properties, 1.5mm thick aluminum veneer usually has certain impact resistance. This is because the main component of aluminum veneer is aluminum alloy, which has good hardness and toughness, and can effectively absorb and disperse external forces, thereby improving the impact resistance of aluminum veneer. The surface of aluminum veneer can also be treated with some special processes, such as anodizing, spraying, etc., to further improve its impact resistance.

In terms of testing methods, commonly used impact resistance testing methods include impact testing and compression testing. The impact test is mainly conducted by simulating the impact of an object on an aluminum veneer to evaluate its impact resistance; The compression test is conducted by applying pressure to test the load-bearing capacity and deformation of aluminum veneer, in order to evaluate its compressive performance. When conducting testing, it is necessary to select appropriate testing equipment and samples, and operate and record data according to relevant standards and specifications.

Again, in terms of data analysis, it is necessary to analyze and evaluate the test results. Based on the test results, it can be determined whether the impact resistance of aluminum veneer meets the requirements and identify its shortcomings. On this basis, corresponding measures can be taken to improve the impact resistance of aluminum veneer, such as adding reinforced structures, using shock-absorbing materials, etc.

In terms of quality inspection and acceptance, it is also necessary to check and evaluate the impact resistance of aluminum veneer. During this process, it is necessary to pay attention to factors such as the dimensional accuracy, surface smoothness, and color uniformity of the aluminum veneer to ensure that its impact resistance meets the requirements.

The impact resistance of 1.5mm thick aluminum veneer is one of its very important advantages. In practical applications, attention should be paid to the quality and effectiveness of the selected materials to ensure better decorative and usage effects, while also paying attention to the impact resistance and construction details of the materials.

Customer service QQ

Customer service QQ