Industry information

Company News

- Aluminum veneer customization: creating an artistic journey of exclusive space

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: the "green coat" of modern architecture

- Aluminum veneer: the architectural wisdom behind lightness

- Fluorocarbon aluminum veneer: the new darling of modern architecture, revealing its charm

Industry dynamics

- Aluminum alloy air conditioning cover: a perfect combination of fashion and practicality

- Do you know the story behind "aluminum veneer"?

- Aluminum veneer customization, creating the art of personalized space

- What is the shrinkage rate of aluminum veneer?

- Fluorocarbon aluminum veneer: the 'hidden hero' of modern architecture

Frequently asked questions

- What are the manufacturers of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the value of recycling and reusing aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production equipment and technological progress of aluminum veneer, as well as the development trend of automation production

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 23, 2025 01:21:16

- Click:0

The production equipment and technological progress of aluminum veneer, as well as the development trend of automation production

Abstract: With the rapid development of industrialization and urbanization, aluminum veneer, as a new type of building material, has been widely used in exterior wall decoration of buildings. This article will elaborate on the production equipment and technological progress of aluminum veneer, as well as the development trend of automated production, from the following four aspects.

1、 Material selection and processing technology

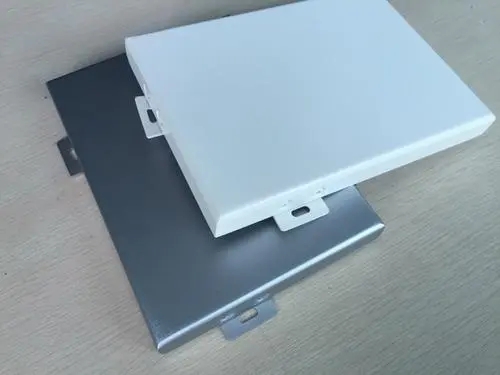

1. Material selection: High quality aluminum materials are required for the production equipment of aluminum veneer to ensure the strength and durability of the product. At present, with the advancement of technology, the application of new alloy aluminum materials continues to expand, such as the 6000 series and 7000 series aluminum alloys, which have higher strength and corrosion resistance.

2. Material processing technology: In the production process of aluminum veneer, cutting, punching, bending and other processes are required. With the continuous development of numerical control technology, traditional manual operations are being replaced by automated equipment. For example, the application of CNC cutting machines and CNC bending machines can achieve high-precision and high-efficiency machining.

3. Surface treatment technology: The surface treatment of aluminum veneer directly affects the aesthetics and weather resistance of the product. At present, commonly used surface treatment methods include spraying, fluorocarbon spraying, and anodizing. These technologies can not only meet the requirements of anti-corrosion and weather resistance for products, but also enhance the decorative effect of products.

2、 Automation of production equipment

1. Application of CNC equipment: In the traditional production process of aluminum veneer, due to the heavy reliance on manual operation, there are problems of low production efficiency and poor process stability. With the widespread application of CNC technology, equipment such as CNC cutting machines, CNC stamping machines, and CNC bending machines can achieve automated production, improving production efficiency and product quality.

2. Intelligent control system: In the production process of aluminum veneer, the application of intelligent control system can achieve comprehensive monitoring and regulation of the production process. For example, using sensors and automated control systems to achieve real-time monitoring and adjustment of parameters such as temperature, humidity, and pressure has improved the stability and consistency of production.

3. Data analysis and optimization: With the development of artificial intelligence and big data technology, it is possible to improve production efficiency and product quality by analyzing and optimizing data in the production process. For example, using machine learning algorithms to analyze production data, optimize production parameters, reduce resource waste and product defects.

3、 Energy saving and environmental protection technology

1. Energy utilization optimization: The energy consumption in the production process of aluminum veneer is mainly concentrated in material processing and surface treatment. By optimizing equipment and process parameters, reducing energy consumption and waste, and adopting high-efficiency energy-saving equipment and technology, energy consumption in the production process can be significantly reduced.

2. Waste disposal: During the production process of aluminum veneer, a large amount of waste is generated, such as cutting residues and surface treatment waste liquids. Through reasonable waste disposal technologies such as recycling and material circulation, environmental pollution can be reduced.

3. Green design and use: In the production and use of aluminum veneer, attention should be paid to the concept of green design and use. For example, measures such as selecting environmentally friendly coatings and materials, optimizing product structure to reduce material usage, and encouraging product reuse and recycling.

4、 Outlook on Development Trends

1. Intelligent production: With the continuous development of artificial intelligence and Internet of Things technology, aluminum veneer production will move towards the direction of intelligence. Through the application of smart devices and analysis of production data, automation and optimization of the production process can be achieved, improving production efficiency and product quality.

2. Green and sustainable development: With the increasing global awareness of environmental protection, aluminum veneer production will pay more attention to green and sustainable development. The future development direction of the aluminum veneer industry is to adopt environmentally friendly materials and processes, reduce energy consumption and waste generation, and promote the application of circular economy models.

3. Innovation and diversification: With the intensification of market competition, aluminum veneer production equipment and technology will continue to innovate. For example, developing faster and more precise processing equipment, and developing more creative and personalized surface treatment technologies to meet the constantly changing needs of customers.

5、 Summary:

With the widespread application of aluminum veneer in building exterior wall decoration, the production equipment and technology of aluminum veneer are also constantly improving and developing. Through the improvement of material selection and processing technology, automation of production equipment, application of energy-saving and environmental protection technology, and prospects for future development trends, the aluminum veneer industry will develop towards a more efficient, environmentally friendly, and innovative direction.

Customer service QQ

Customer service QQ