Industry information

Company News

- Fluorocarbon aluminum veneer: the fashionable "coat" of modern architecture

- Aluminum veneer customization: an artistic journey to create personalized spaces

- Aluminum veneer: a fashionable new favorite for creating modern architecture

- Aluminum veneer: the beauty of industry, the charm of simplicity

- Aluminum alloy air conditioning cover: the secret weapon to protect the coolness of summer

Industry dynamics

- Aluminum veneer: a perfect combination of lightness and strength

- Fluorocarbon aluminum veneer: a fashionable choice in modern architecture?

- Aluminum veneer customization, creating a unique spatial aesthetic

- Fluorocarbon aluminum veneer: a perfect combination of architectural aesthetics and environmental protection

- Fluorocarbon aluminum veneer: the new favorite of architectural aesthetics, one board, one world

Frequently asked questions

- What is the price of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

- What is the production process of aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

How to ensure the anti-corrosion performance of punched aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 14, 2025 13:42:39

- Click:0

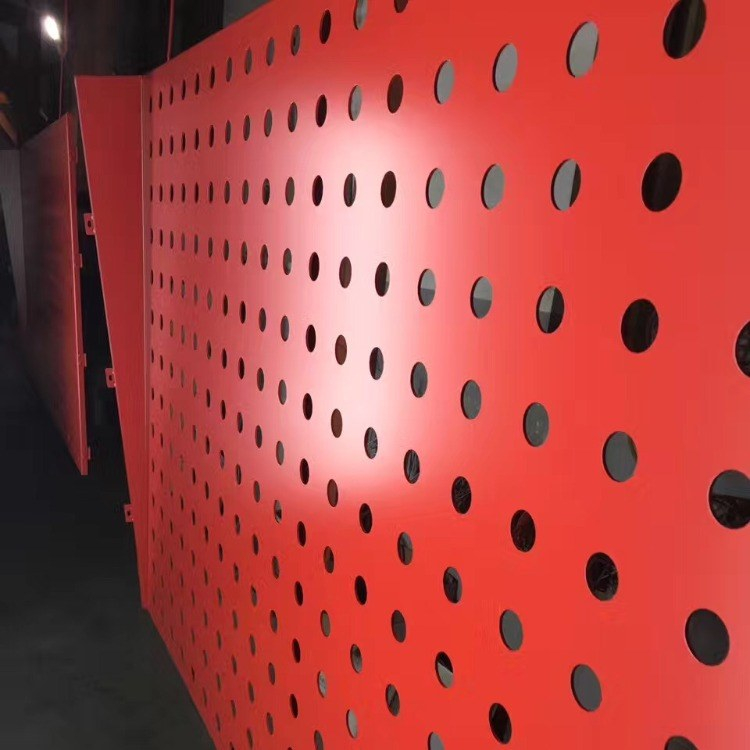

Punched aluminum veneer, as a widely used material in fields such as architectural decoration, billboards, curtain walls, etc., its anti-corrosion performance is also an important aspect. The anti-corrosion performance can affect the service life and safety of punched aluminum veneer. The following will introduce how to ensure the anti-corrosion performance of punched aluminum veneer from the following aspects.

1. Strengthen surface treatment process

Surface treatment is one of the important factors affecting the anti-corrosion performance of punched aluminum veneer. Strengthening the surface treatment process can improve the durability and corrosion resistance of punched aluminum veneer. Specifically, surface treatment can be carried out in the following ways:

(1) Adopting anodizing treatment to increase surface hardness and wear resistance;

(2) Adopting electrophoretic coating or spray coating technology to improve coating thickness and uniformity;

(3) Coatings with good weather resistance and corrosion resistance, such as fluorocarbon paint, are used.

1. Avoid prolonged exposure to sunlight or rainy or snowy weather

Long term exposure to sunlight or rainy or snowy weather can cause color differences and corrosion on the surface of perforated aluminum veneer, thereby reducing its anti-corrosion performance. When using perforated aluminum veneer, it is necessary to avoid prolonged exposure to sunlight or rainy or snowy weather. Suitable shading measures can be chosen, such as building sunshades, installing canopies, etc.

1. Avoid collisions and scratches

Collisions and scratches can cause scratches and dents on the surface of punched aluminum veneer, thereby affecting its aesthetics and corrosion resistance. When using punched aluminum veneer, attention should be paid to avoiding collisions and scratches, and appropriate protective measures can be taken, such as fixing measures or using protective pads for protection.

How to ensure the anti-corrosion performance of punched aluminum veneer?

To ensure the anti-corrosion performance of punched aluminum veneer, the following measures can be taken:

(1) Choose coating materials with good durability and corrosion resistance;

(2) Strengthen surface treatment processes to improve their compressive, tensile, and impact resistance properties;

(3) Avoid prolonged exposure to sunlight or rainy or snowy weather;

(4) Avoid collisions and scratches, and take appropriate protective measures;

(5) Regularly inspect and maintain the surface condition and structural integrity of punched aluminum veneer, and promptly address any potential problems and malfunctions.

Customer service QQ

Customer service QQ