Industry information

Company News

- Aluminum veneer: understated luxury in modern architecture

- The charm of aluminum veneer: the perfect combination of lightness and texture

- Customize aluminum veneer to create your own space aesthetic

- Fluorocarbon aluminum veneer: the new darling of modern architecture

- Aluminum Guardian, Cool Summer: The Secret of Aluminum Alloy Air Conditioning Hood

Industry dynamics

- Aluminum alloy air conditioning cover: cool summer, guarding the new fashion of home furnishings

- How much is the price of fluorocarbon aluminum veneer per square meter and how is it calculated?

- Aluminum veneer: the new favorite of light luxury decoration, creating a fashionable home space

- Aluminum veneer customization makes your project stand out from the crowd

- Market Analysis and Research Report on Aluminum Veneer Prices

Frequently asked questions

- What is the value of recycling and reusing aluminum veneer?

- What is the production process of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of Precision Aluminum Veneer Customization Process

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 2, 2025 00:05:08

- Click:0

Aluminum veneer customization is a new type of building material that has the advantages of lightweight, high strength, corrosion resistance, fire resistance, etc., and has therefore been widely used in the construction industry. To achieve precise customization of aluminum veneer, a series of processes and steps are required. Below, we will analyze the process of precision aluminum veneer customization from multiple perspectives.

1、 Requirement analysis

Requirement analysis is the first and crucial step in customizing aluminum veneer. At this stage, it is necessary to have a comprehensive understanding and analysis of the customer's needs, including architectural style, functional use, decorative requirements, and other aspects. Only by fully understanding the needs of customers can we provide them with more accurate customized services.

2、 Design proposal

Based on demand analysis, aluminum veneer manufacturers need to provide multiple design solutions for customers to choose from according to their needs. The design scheme needs to consider multiple aspects such as the overall style, functional use, and decorative requirements of the building to ensure that the final customized effect meets the customer's expectations.

3、 Material selection

Material selection is one of the important steps in customizing aluminum veneer. High quality aluminum veneer materials can improve the quality and performance of products, enhancing their market competitiveness. At this stage, it is necessary to select suitable materials according to the requirements of the design scheme and conduct quality testing and evaluation on them.

4、 Production and processing

Production and processing are one of the core processes in customizing aluminum veneer. At this stage, advanced production processes and technologies are needed to finely process and treat aluminum veneers to ensure that the final product meets design requirements and quality standards. We also need to strengthen the management and control of the production process to ensure the stability and consistency of product quality.

5、 Surface treatment

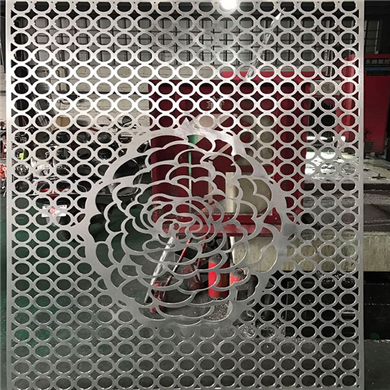

Surface treatment is one of the important steps in customizing aluminum veneer. By anodizing, electrophoretic coating, powder coating and other treatment methods, the hardness and wear resistance of aluminum veneer can be improved, and a protective film can be formed to prevent oxidation and corrosion of aluminum veneer.

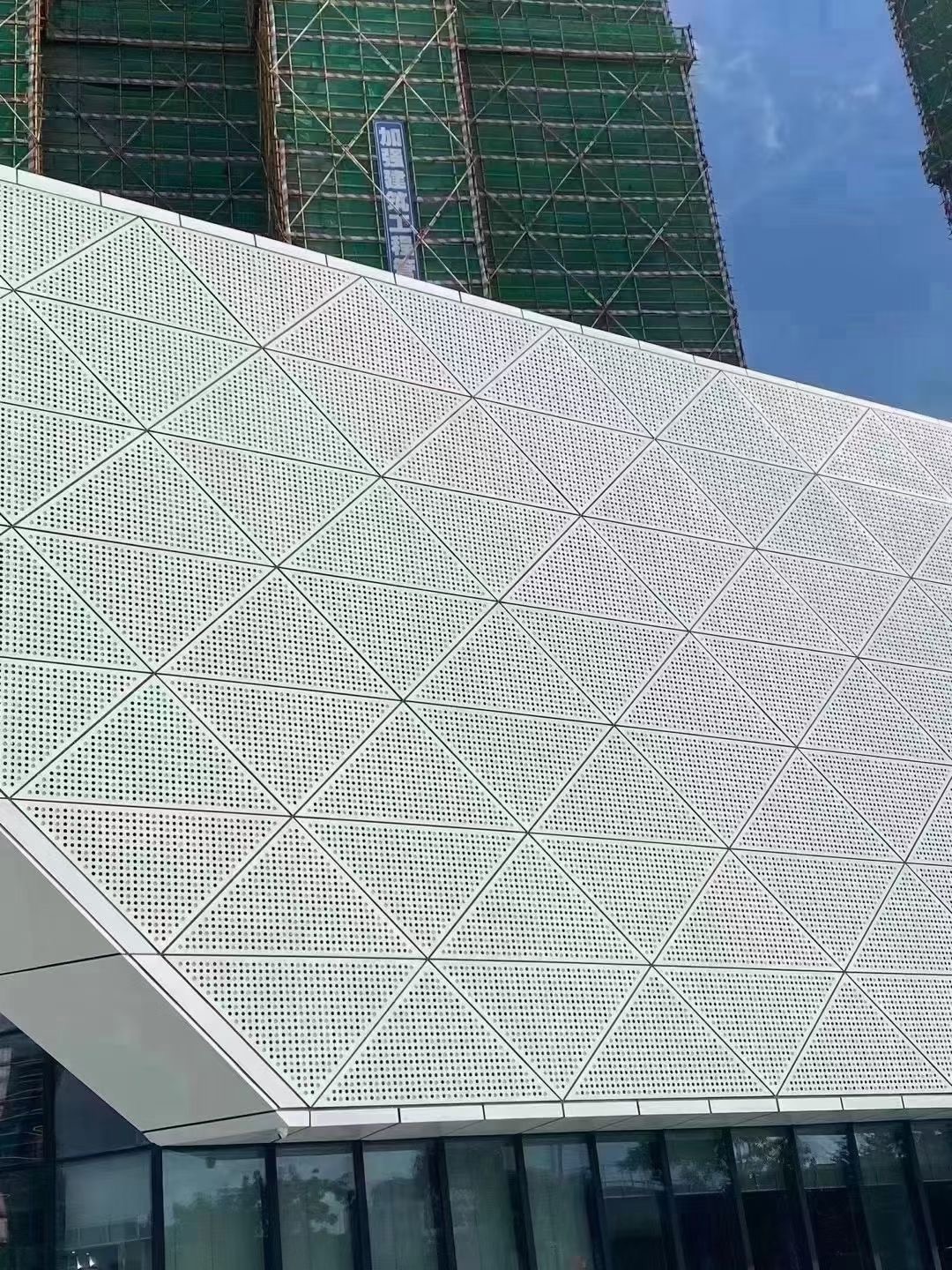

6、 Installation and construction

Installation and construction are the final and crucial steps in customizing aluminum veneer. At this stage, it is necessary to strictly follow the design plan and construction specifications for installation and construction to ensure that the final product meets the design requirements and quality standards. We also need to strengthen on-site management to ensure the safety and quality of construction.

7、 Case sharing

By sharing practical cases, we can gain a more intuitive understanding of how to achieve precise aluminum veneer customization. For example, a certain hotel used customized aluminum veneer as the exterior wall decoration material, and through the design and surface treatment of the aluminum veneer, created a unique architectural appearance. For example, a certain commercial square uses customized aluminum veneers as interior decoration materials, and creates a unique commercial atmosphere through the design and color matching of aluminum veneers.

8、 Summary

The above is a detailed introduction to the precision aluminum veneer customization process. Requirement analysis, design scheme, material selection, production and processing, surface treatment, installation and construction are key factors affecting the customization of aluminum veneer. In the future, with the continuous advancement of technology and the development of innovation, we believe that there will be more outstanding enterprises emerging in the aluminum veneer industry, bringing people a better living experience and making greater contributions to environmental protection.

Customer service QQ

Customer service QQ