Industry information

Company News

- Fluorocarbon aluminum veneer: the new darling of modern architecture

- Aluminum alloy air conditioning cover: the secret weapon to protect the coolness of the home!

- Aluminum veneer: creating a new style of modern architecture

- Fluorocarbon aluminum veneer: the "invisible warrior" of modern architecture

- Aluminum alloy air conditioning cover: the guardian of coolness in summer

Industry dynamics

- The unique charm of carved hollow aluminum veneer in landscape design

- The latest trend design of aluminum veneer

- Fluorocarbon aluminum veneer: creating a new fashion in modern architecture

- Railway shaped aluminum veneer device

- Aluminum veneer: the 'hidden hero' in architecture

Frequently asked questions

- What are the manufacturers of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

- What is the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the shrinkage rate of aluminum veneer?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 13, 2025 06:55:03

- Click:0

Aluminum veneer, as a new type of building material, has attracted much attention for its shrinkage rate. Let's take a look at the shrinkage rate of aluminum veneer together.

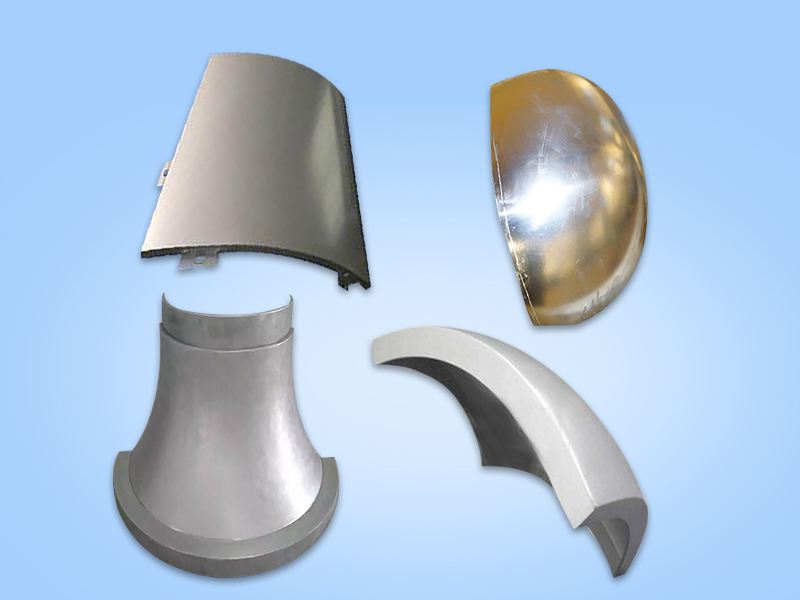

The material of aluminum veneer has an impact on its shrinkage rate. Generally speaking, pure aluminum has a higher shrinkage rate, while some alloy materials, such as aluminum alloys, magnesium alloys, etc., have lower shrinkage rates. These alloy materials have added some special elements such as lithium, zirconium, copper, etc. during the manufacturing process, which can effectively reduce their shrinkage rate.

The use and environment of aluminum veneer can also affect its shrinkage rate. For example, using aluminum veneer in high temperature environments will increase its shrinkage rate; When using aluminum veneer in low-temperature environments, its shrinkage rate will decrease. During use, attention should be paid to avoiding adverse effects such as scratching, impact, and contamination on aluminum veneer, in order to prevent damage to its surface protective layer or internal structure, thereby affecting its shrinkage rate.

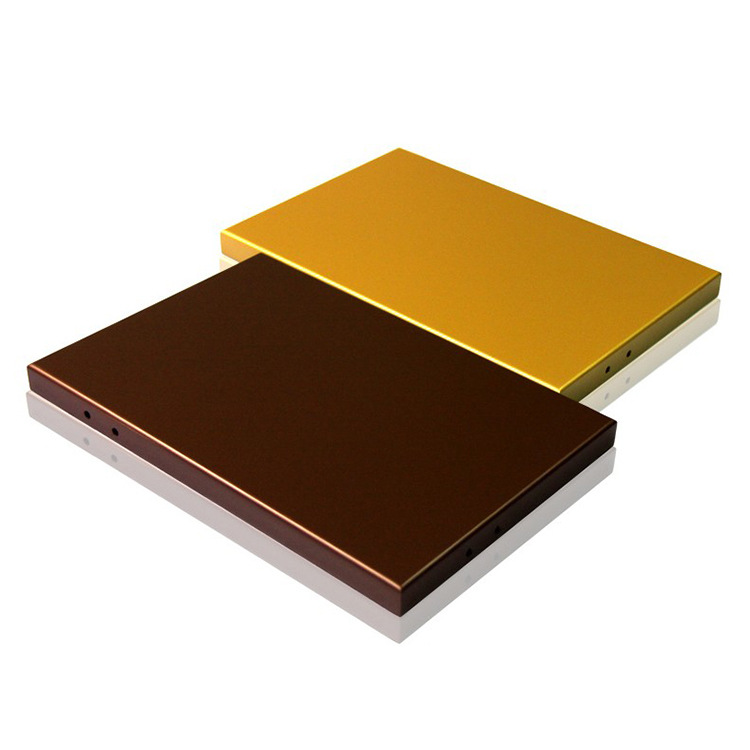

The shrinkage rate of aluminum veneer refers to its length change rate at different temperatures. Normally, the shrinkage rate of aluminum veneer ranges from 10 to 50 microns per degree Celsius. This range is relatively large, so the influence of shrinkage rate needs to be considered in the design and construction process of aluminum veneer.

To minimize the impact of aluminum veneer shrinkage on buildings, the following measures can be taken:

1. Fully consider the shrinkage rate of aluminum veneer in the design and construction process, arrange its position and size reasonably, and avoid excessive shrinkage deformation.

2. Before installing aluminum veneer, reserve holes or set expansion joints to allow for free expansion and contraction during temperature changes without affecting the overall stability of the building.

3. After installing the aluminum veneer, conduct regular inspections and maintenance to promptly identify and repair problems caused by shrinkage.

The shrinkage rate of aluminum veneer is an important parameter that directly affects the service life of aluminum veneer and the overall stability of buildings. Through reasonable design and construction methods, as well as regular inspection and maintenance, the impact of aluminum veneer shrinkage on buildings can be minimized to the greatest extent possible.

Customer service QQ

Customer service QQ