Industry information

Company News

- Customize aluminum veneer to create personalized space art

- Fluorocarbon aluminum veneer, the "fashionable outerwear" of modern architecture

- Aluminum veneer, the 'invisible magician' of the construction industry

- Aluminum veneer: the fashionable "coat" of modern architecture

- Fluorocarbon aluminum veneer: the fashionable choice for modern architecture?

Industry dynamics

- Production equipment and automated production process for aluminum veneer

- Aluminum veneer: the fashionable outerwear of modern architecture

- Aluminum veneer creates a unique texture for modern architecture

- Aluminum veneer: the fashionable choice for modern architecture?

- Aluminum alloy air conditioning cover: a secret weapon for keeping your home cool in summer!

Frequently asked questions

- What is the corrosion resistance of aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

- What is the value of recycling and reusing aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the price of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Customization process requirements for aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: March 18, 2025 03:24:17

- Click:0

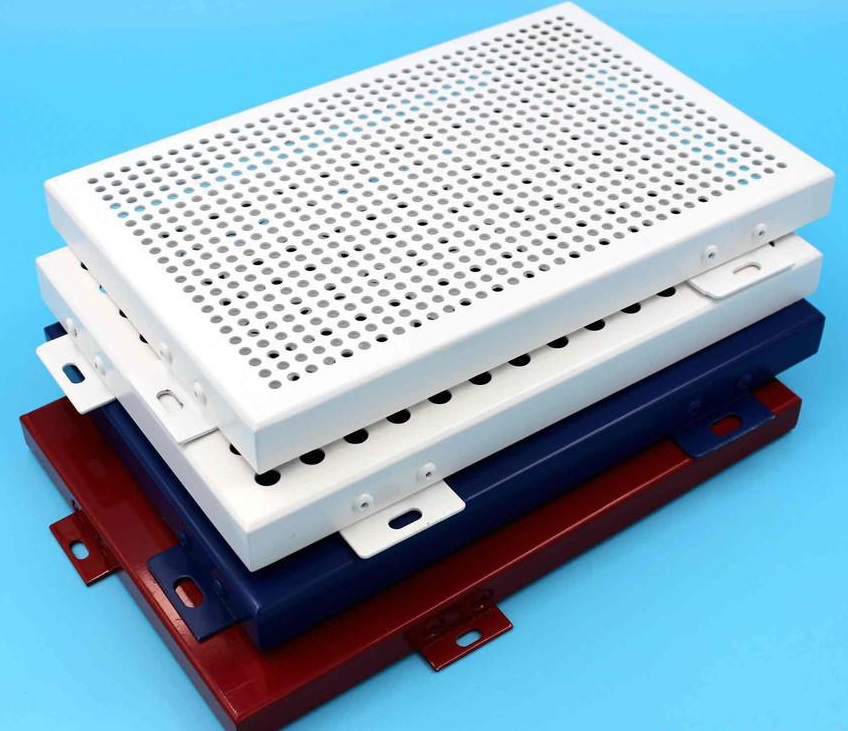

As a new type of building decoration material, the process requirements for customized aluminum veneer are also very important. Below, we will provide a detailed introduction to the customization process requirements for aluminum veneer.

1、 Raw material preparation

Before customizing aluminum veneer, sufficient preparation of raw materials is required. To choose high-quality 3003 series aluminum veneer as raw material; Surface treatment should be carried out on aluminum veneer to improve its corrosion resistance and aesthetics; Thickness and color selection should be based on actual needs.

2、 Processing and Manufacturing

The processing and production of aluminum veneer is the most critical step in the entire customization process. Generally speaking, the processing and production of aluminum veneer includes the following steps: cutting, bending, punching, welding, polishing, and painting. Cutting is the process of cutting aluminum veneer into the desired shape and size according to design requirements; Bending is the process of bending aluminum veneer into the desired angle and shape according to design requirements; Punching is the process of punching the required holes into an aluminum veneer according to design requirements; Welding is the process of welding aluminum veneer according to design requirements; Polishing is the process of polishing the surface of aluminum veneer to improve its smoothness and aesthetics; Spray painting is the process of applying the desired color and protective film onto the surface of aluminum veneer.

3、 Installation and construction

The installation and construction of aluminum veneer is also a crucial step in the entire customization process. Generally speaking, the installation and construction of aluminum veneer includes the following steps: measurement, positioning, keel installation, hoisting, fixing, and inspection. Measurement and positioning are key steps to ensure the accurate installation position of aluminum veneer; The installation of the keel is a crucial step in connecting the aluminum veneer to the keel; Lifting is a key step in lifting aluminum veneer to a designated location; Fixation is a key step in firmly fixing aluminum veneer to the keel; Inspection is a key step in checking the installation quality of aluminum veneer.

4、 Quality inspection

The quality inspection of aluminum veneer is a very important step, which directly affects the effectiveness and safety of its use. Generally speaking, the quality inspection of aluminum veneer includes the following aspects: appearance inspection, size inspection, strength inspection, corrosion resistance inspection, and safety performance inspection. Only through strict quality inspection can the quality and safety of aluminum veneer be guaranteed.

The customization process requirements for aluminum veneer are very important. Only through scientific technology can we create higher quality, more beautiful, and practical aluminum veneer products. We believe that with everyone's joint efforts, the customized aluminum veneer market will usher in a better development prospect.

Customer service QQ

Customer service QQ