Production equipment and automated production process for aluminum veneer

Abstract: This article will provide a detailed introduction to the production equipment and automated production process of aluminum veneer. Firstly, we will elaborate on the following four aspects: raw material preparation, sheet metal processing, surface treatment, and quality control. By conducting a detailed analysis of these aspects, we can gain a better understanding of the production process of aluminum veneer.

1、 Raw material preparation

In the production of aluminum veneer, preparing raw materials is a crucial step. Firstly, it is necessary to choose high-quality aluminum alloy materials to ensure the quality of the final product. Then, the material enters the cutting area and is cut using automated equipment to obtain the desired size and shape. Next, in order to improve the performance of aluminum veneer, it is necessary to heat treat the material to enhance its hardness and corrosion resistance. The application of automation equipment plays a crucial role in the process of raw material preparation. The use of automatic cutting robots can improve cutting efficiency and accuracy while ensuring the safety of operators. In addition, intelligent heating equipment can be controlled according to different requirements to ensure that the heat treatment effect of materials meets expectations.

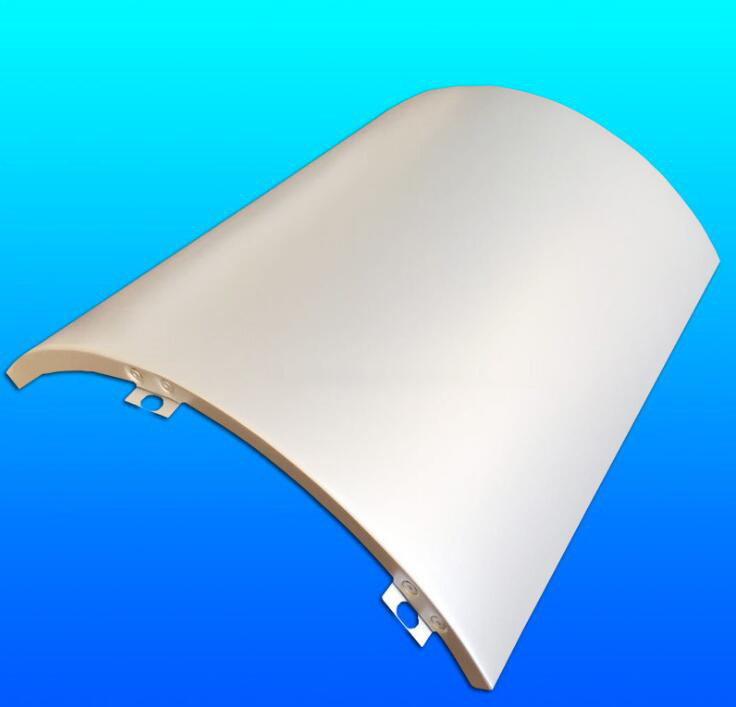

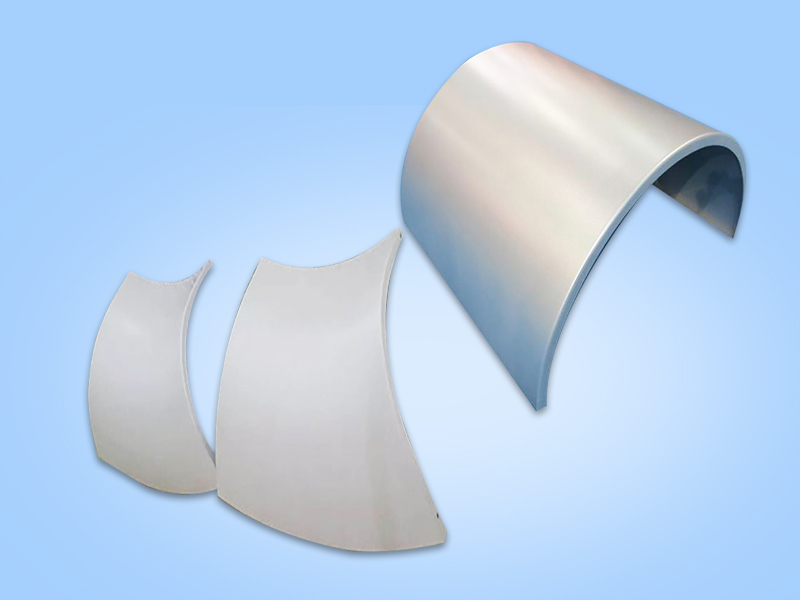

2、 Sheet metal processing

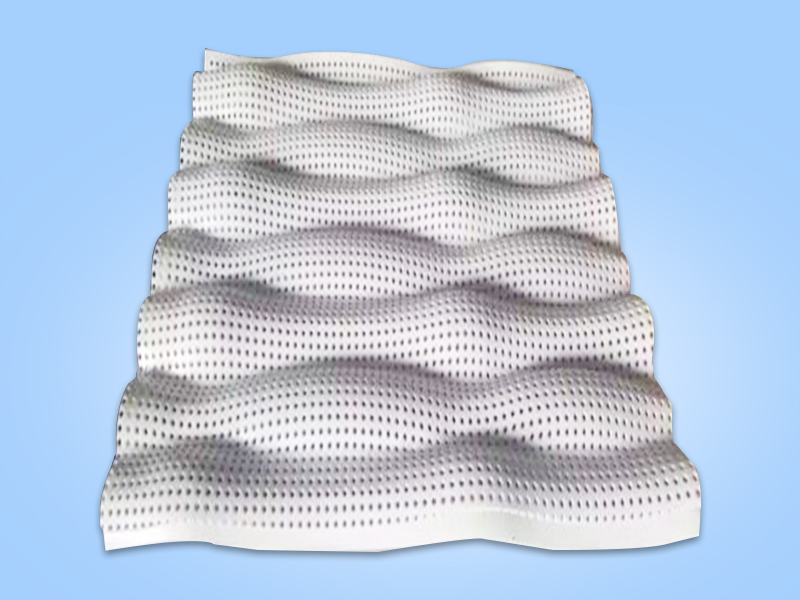

After the raw material preparation is completed, the next step is the processing of the sheet metal. The common processing methods for aluminum veneer include cutting, bending, punching, and welding. Through the application of automated equipment, efficient and precise processing can be achieved. Firstly, the sheet needs to be cut by a shearing machine to obtain the desired size. Then, use an automatic bending machine to bend the sheet metal to produce the desired shape and angle. Next, the punching machine will punch holes on the board according to the design requirements to facilitate subsequent installation and suspension. Finally, different components are welded using welding equipment to assemble the final aluminum veneer product. Automated sheet metal processing equipment greatly improves production efficiency and product quality. Through the application of numerical control technology, high-precision cutting and processing can be achieved, reducing the occurrence of human errors while saving human resources and time costs.

3、 Surface treatment

The surface treatment of aluminum veneer is to increase its aesthetics and corrosion resistance. Common surface treatment methods include anodizing, spraying, and powder coating. Automation equipment plays an important role in the process of surface treatment. Firstly, through automated spraying equipment, aluminum veneer can be color sprayed to give it a rich appearance effect. Then, using automated powder coating equipment, a uniform and durable coating can be formed on the surface of aluminum veneer, improving the product's corrosion resistance and weather resistance. At the same time, the automatic control system can achieve precise control of the thickness and quality of the coating, ensuring that each product meets the requirements.

4、 Quality control

Quality control is an indispensable part of the aluminum veneer production process. Through the application of automation equipment and advanced technology, precise control and monitoring of product quality can be achieved. Firstly, through automated testing equipment, the size, angle, and shape of the board can be accurately measured to ensure that the product meets the design requirements. Then, after surface treatment is completed, the coating is subjected to quality inspection through automated equipment to check for scratches, bubbles, or uneven coating. Finally, through automated packaging equipment, finished aluminum veneers can be packaged and labeled to ensure product safety and traceability. Summary: Through a detailed explanation of the production equipment and automated production process of aluminum veneer, we can see that automated equipment plays an important role in improving production efficiency, ensuring product quality, and reducing costs. With the continuous advancement of technology, the production of aluminum veneer will become more intelligent and efficient, bringing more possibilities to the construction industry.

Customer service QQ

Customer service QQ