Corporate News

Company News

- Aluminum veneer customization, creating a new trend of personalized space

- Aluminum alloy air conditioning cover: the guardian of coolness in summer homes

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- The magnificent transformation of aluminum veneer: the new darling of modern architecture

- Unveiling Fluorocarbon Aluminum Veneer: A New Favorite in Fashion Architecture and a New Force in Environmentally Friendly Building Materials!

Industry dynamics

- Aluminum veneer: a perfect combination of lightness and strength

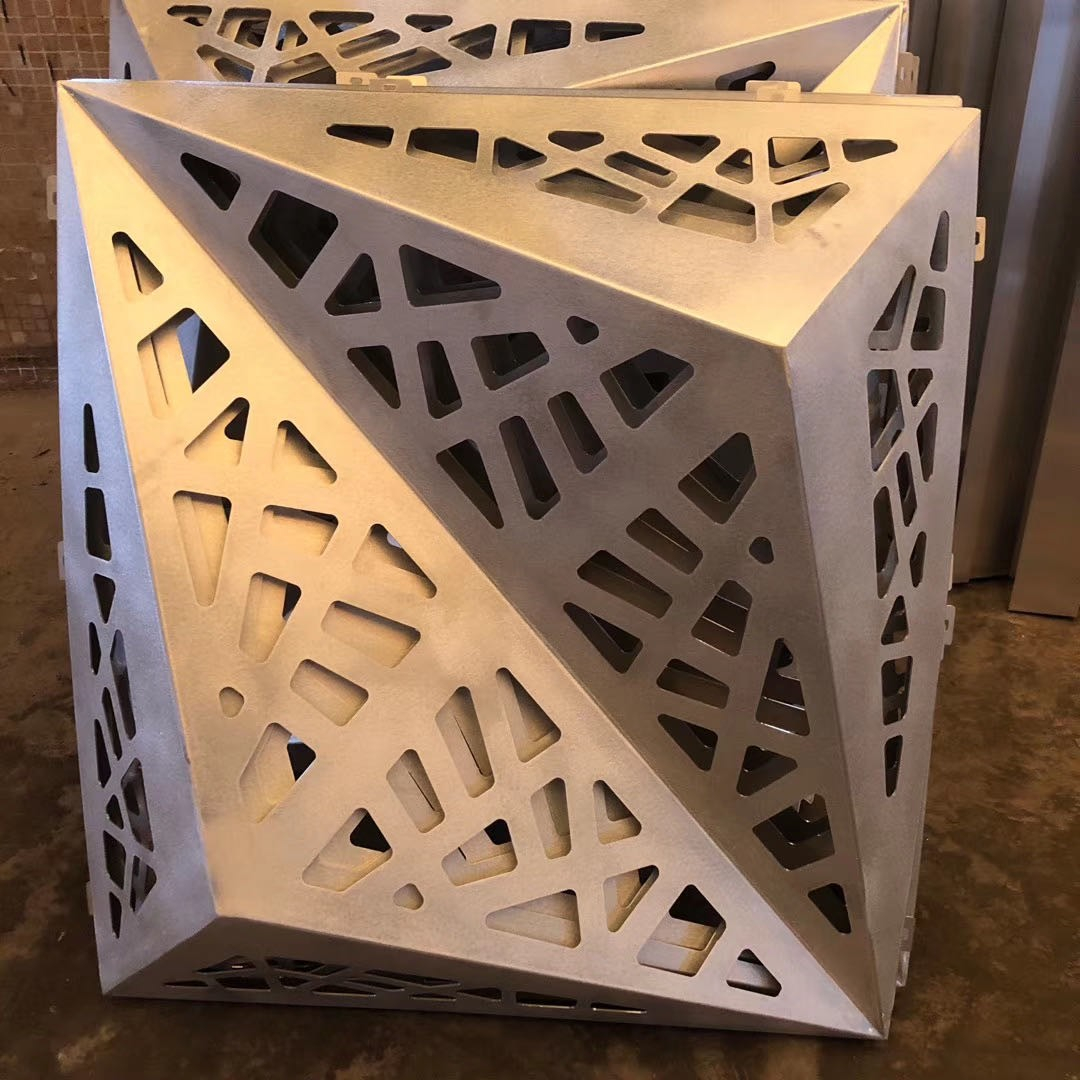

- Application fields and future development prospects of special-shaped perforated aluminum veneer

- Analysis of the production process of aluminum veneer and its advantages in use

- Aluminum alloy air conditioning cover: guarding summer coolness, fashionable upgrade

- Fluorocarbon aluminum veneer: a fashionable choice in modern architecture?

Frequently asked questions

- What are the manufacturers of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

- What is the price of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to the production process and equipment of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 22, 2025 21:29:22

- Click:0

Introduction to the production process and equipment of aluminum veneer

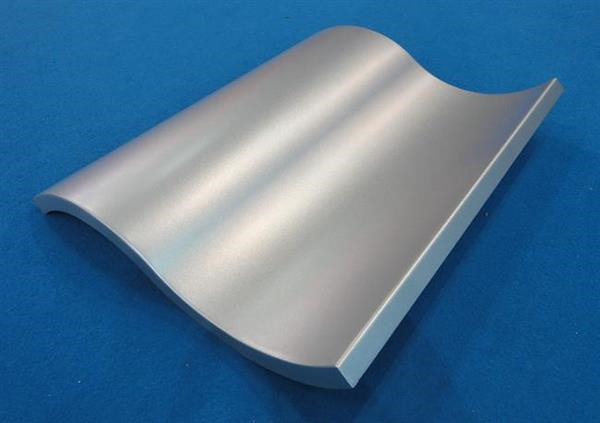

With the continuous development and changes of the architectural decoration market, aluminum veneer as an exterior wall building material has gradually attracted market attention. Aluminum veneer has the characteristics of light weight, high strength, fire resistance, and durability. At the same time, its surface can be processed in various ways, making its shape and color more diverse. This article will introduce the production process and equipment of aluminum veneer from four aspects.

1、 Production process of aluminum veneer

1. Raw material processing: Firstly, the aluminum plate needs to undergo pre-treatment processes such as cutting and trimming, in order to facilitate the subsequent forming and processing.

2. Forming processing: This step mainly involves bending, cutting, punching, stretching and other processes on aluminum plates to meet different styling requirements.

3. Surface treatment: This step mainly involves surface treatment such as oxidation and spraying of aluminum plates to increase their durability and aesthetics.

4. Finished product quality inspection: After the production of aluminum veneer is completed, some necessary quality inspection work needs to be carried out to ensure that the product quality meets the standards.

2、 Aluminum veneer production equipment

Aluminum veneer, as a high-end building material, requires a series of professional equipment for processing and treatment in its production process. The common devices include the following:

1. Scissor machine: mainly used for cutting and trimming raw aluminum plates.

2. Punching machine: mainly used for punching aluminum plates.

3. Bending machine: mainly used for bending aluminum plates.

4. Stretching machine: mainly used for stretching aluminum plates.

5. Spraying equipment: mainly used for surface spraying of aluminum plates.

3、 Surface treatment technology for aluminum veneer

Surface treatment of aluminum veneer is a very important step in the production of aluminum veneer. Different surface treatment techniques can make aluminum veneer different in appearance, performance, and other aspects. Common surface treatment techniques include:

1. Oxidation treatment: can increase the corrosion resistance, wear resistance, and hardness of aluminum plates.

2. Electrophoretic coating: can increase the corrosion resistance, weather resistance, and color diversity of aluminum plates.

3. Fluorocarbon coating: can increase the weather resistance, UV resistance, and dust resistance of aluminum plates.

4、 Aluminum veneer installation process

After the production of aluminum veneer is completed, installation work still needs to be carried out. The installation of aluminum veneer generally involves the following steps:

1. Develop construction plan: Develop installation plan based on site conditions, determine installation materials, tools, etc.

2. Aluminum veneer laying: Lay the aluminum veneer according to the predetermined plan.

3. Fixed aluminum veneer: Use professional tools to fix the aluminum veneer onto the foundation structure.

4. Inspection and acceptance: After installation, quality inspection and acceptance work are also required.

5、 Summary

Aluminum veneer, as a high-end building decoration material, its production process and equipment are very important. This article provides a detailed introduction to the key links in the production process of aluminum veneer from four aspects: production process, production equipment, surface treatment technology, and installation process. I hope this article can be helpful for readers to understand aluminum veneer.

Customer service QQ

Customer service QQ