Industry information

Company News

- Aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

- Unveiling Fluorocarbon Aluminum Veneer: A New Favorite in Fashion Architecture and a New Force in Environmentally Friendly Building Materials!

- Aluminum veneer, the hidden beauty in modern architecture

- Fluorocarbon aluminum veneer: the new darling of modern architecture, your home upgrade tool!

Industry dynamics

- The development trend of production technology for aluminum veneer

- The new trend of aluminum veneer decoration is about to ignite a light luxury lifestyle!

- Aluminum alloy air conditioning cover: the guardian of home aesthetics

- Fluorocarbon aluminum veneer: the new darling of modern architecture, revealing its charm!

- Market demand analysis of customized aluminum veneer

Frequently asked questions

- What is the corrosion resistance of aluminum veneer?

- What are the manufacturers of aluminum veneer and how to choose?

- What is the wind pressure resistance performance of aluminum veneer?

- What is the environmental performance of aluminum veneer?

- What is the production process of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Production technology and equipment maintenance of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 23, 2025 11:00:05

- Click:0

Production technology and equipment maintenance of aluminum veneer

Abstract: This article will elaborate on the production technology and equipment maintenance of aluminum veneer, including raw material preparation, processing technology, quality control, and equipment maintenance. Aluminum veneer, as a commonly used decorative material, has a wide range of applications in the fields of architecture and interior design. Understanding its production technology and equipment maintenance is crucial for ensuring product quality and extending equipment lifespan.

1、 Raw material preparation

1. Raw material selection: The main raw material used in the production of aluminum veneer is high-purity aluminum alloy sheet. When selecting raw materials, it is necessary to consider the composition and properties of aluminum alloys to ensure the selection of suitable raw materials.

2. Raw material processing: Cutting, grinding, and surface treatment processes are carried out on aluminum alloy sheets to ensure a smooth and clean surface, preparing for subsequent processing techniques.

3. Raw material storage: When storing aluminum alloy sheets, attention should be paid to avoiding contact with moisture, chemicals, and other metals to prevent material damage or oxidation.

2、 Processing technology

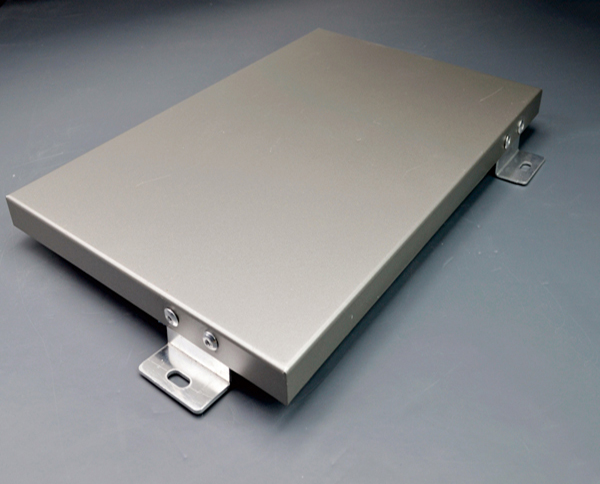

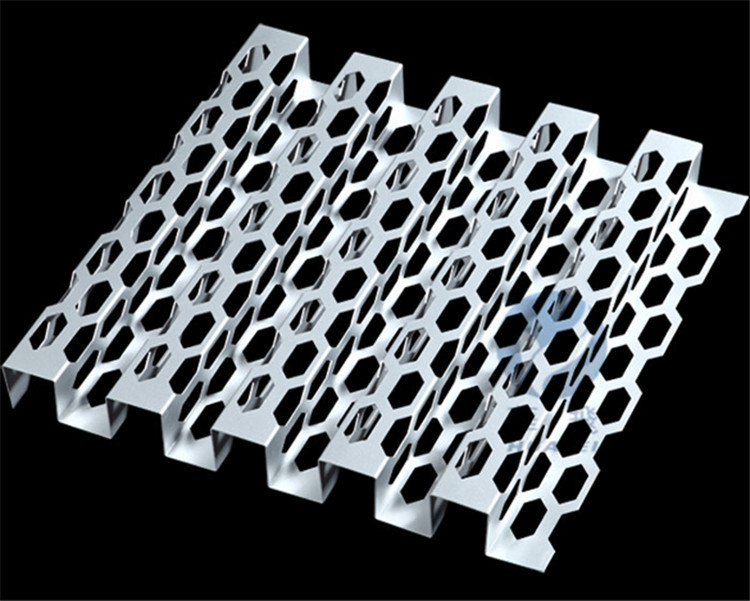

1. Cutting and Forming: Cut and form raw aluminum alloy sheets according to design requirements. Use professional cutting equipment and molds to ensure the accuracy and quality of cutting and forming.

2. Surface treatment: Oil removal, rust removal, and spraying treatment are carried out on the surface of aluminum veneer to improve the quality and durability of the surface. Adopt appropriate surface treatment methods and materials to ensure that the surface treatment effect meets the expected requirements.

3. Assembly and connection: Assemble and connect aluminum veneers to form finished products. During the assembly and connection process, attention should be paid to the flatness and stability of the joints to ensure the strength and stability of the overall structure.

3、 Quality control

1. Strict testing: Each process undergoes strict quality inspection, including inspection of raw materials, control of processing, and sampling testing of finished products. Ensure that the product complies with relevant standards and specifications.

2. Quality records: Establish a comprehensive quality record and archive system to record the quality data and inspection results of each process for traceability and analysis.

3. Continuous improvement: Based on quality data and customer feedback, adjust and improve production processes in a timely manner to enhance product quality and production efficiency.

4、 Equipment maintenance

1. Regular maintenance: Regular maintenance of equipment used in production, including cleaning, lubrication, and replacement of vulnerable parts. Ensure that the equipment is in good working condition, reducing malfunctions and downtime.

2. Troubleshooting: Timely handle equipment malfunctions and identify the cause for repair. Establish a troubleshooting mechanism, strengthen equipment maintenance technical training, and improve troubleshooting efficiency.

3. Update and upgrade: With the development of technology, timely update and upgrade production equipment to improve production capacity and quality.

5、 Summary:

The production technology and equipment maintenance of aluminum veneer are important links to ensure product quality and production efficiency. By proper preparation of raw materials, precise processing techniques, strict quality control, and effective equipment maintenance, high-quality aluminum veneer products can be produced and the lifespan of the equipment can be extended. In future development, production technology and equipment maintenance should be continuously optimized and improved to meet market demand and enhance competitiveness.

Customer service QQ

Customer service QQ