Industry information

Company News

- Aluminum veneer is not just a sheet metal, but also a fashion symbol of modern architecture!

- Aluminum alloy air conditioning cover: the guardian of coolness in summer homes

- Fluorocarbon aluminum veneer: the 'invisible hero' of modern architecture

- Fluorocarbon aluminum veneer: a shining pearl in modern architecture

- Fluorocarbon aluminum veneer: a fashionable new favorite in the construction industry. Do you know about it?

Industry dynamics

- Fluorocarbon aluminum veneer: the 'invisible hero' of modern architecture

- Aluminum veneer customization: creating unique spatial art

- Fluorocarbon aluminum veneer: the chameleon of the construction industry, your new favorite for home decor!

- Fluorocarbon aluminum veneer: the new favorite of light luxury in architectural aesthetics

- Advantages and characteristics of painted aluminum veneer for curtain walls

Frequently asked questions

- What is the corrosion resistance of aluminum veneer?

- What are the manufacturers of aluminum veneer?

- What are the thickness and specifications of aluminum veneer?

- What is the production process of aluminum veneer?

- What is the wind pressure resistance performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

5 surface treatment processes for aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-11 18:53:16

- Click:0

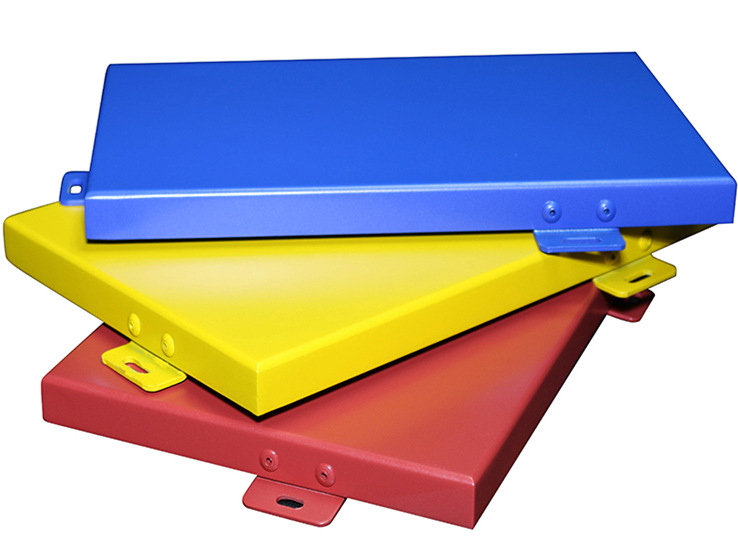

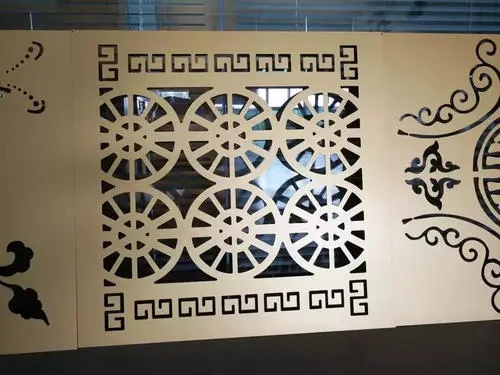

Aluminum veneer, as a new type of building material, has the advantages of lightweight, high strength, and strong decorative properties. The surface treatment process of aluminum veneer is also a very important step, which can not only affect the aesthetics and service life of the entire building, but also reflect the quality and performance characteristics of aluminum veneer. Next, we will introduce 5 surface treatment processes for aluminum veneer.

1. Anodizing: Anodizing is a commonly used surface treatment process for aluminum veneer, which forms an oxide film on the surface of the aluminum veneer through electrolytic oxidation, thereby improving its corrosion resistance and wear resistance. Anodizing can also provide different colors and textures for aluminum veneers, making them more beautiful and elegant.

2. Fluorocarbon spraying: Fluorocarbon spraying is a high-end surface treatment process for aluminum veneer, which forms a uniform and dense coating on the surface of the aluminum veneer by spraying fluorocarbon paint, thereby improving the weather resistance and waterproofing of the aluminum veneer. Fluorocarbon spraying can also provide different colors and glossiness for aluminum veneer, making it more upscale and atmospheric.

3. Powder spraying: Powder spraying is an environmentally friendly surface treatment process for aluminum veneer, which forms a uniform and dense coating on the surface of the aluminum veneer through powder spraying, thereby improving its corrosion resistance and decorative properties. Powder coating can also provide different colors and textures for aluminum veneer, making it more natural and beautiful.

4. Wire drawing oxidation: Wire drawing oxidation is a relatively special surface treatment process for aluminum veneers. By wire drawing the surface of aluminum veneers, it presents a similar effect to metal wire drawing, thereby improving the decorative and texture of aluminum veneers. Drawing oxidation can also provide different colors and textures for aluminum veneer, making it more personalized.

5. Heat transfer printing: Heat transfer printing is a relatively simple surface treatment process for aluminum veneer. By printing patterns or text on heat transfer paper, and then heating and pressing the heat transfer paper on the aluminum veneer, the desired patterns or text can be formed on the aluminum veneer. This processing technique is suitable for some small aluminum veneer products, such as signs, billboards, etc.

The surface treatment process of aluminum veneer is one of the important factors affecting its aesthetics, durability, and decorative properties. Consumers should choose products that meet the requirements based on their actual needs when choosing aluminum veneer, and request relevant testing reports and certificates. It is recommended that consumers pay attention to reasonable use and maintenance when using aluminum veneer to extend its service life and maintain good aesthetics and anti-corrosion performance.

Customer service QQ

Customer service QQ