Industry information

Company News

- Fluorocarbon aluminum veneer: the new darling of modern architecture, your home upgrade tool!

- Aluminum alloy air conditioning cover: elegant home style, one cover determines the universe

- Aluminum veneer customization, creating a new trend of personalized space

- How much do you know about aluminum veneer: a fashionable choice for modern architecture?

- Fluorocarbon aluminum veneer: a fashionable outerwear for modern architecture

Industry dynamics

- In depth analysis of aluminum veneer customization industry

- Aluminum alloy air conditioning cover: the guardian of coolness in summer homes

- 5 surface treatment processes for aluminum veneer

- Aluminum veneer: the secret weapon of architectural aesthetics

- Analysis of Precision Aluminum Veneer Customization Process

Frequently asked questions

- How to improve the environmental performance of aluminum veneer?

- What is the value of recycling and reusing aluminum veneer?

- What are the manufacturers of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

- What is the price of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

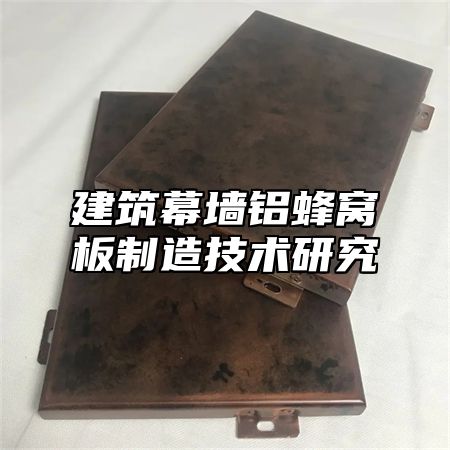

Research on Manufacturing Technology of Aluminum Honeycomb Panels for Building Curtain Walls

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 28, 2025 06:56:01

- Click:0

Aluminum honeycomb panel for building curtain walls is a new type of building material that is characterized by lightweight, high strength, corrosion resistance, and easy cleaning. It is widely used in various fields such as commercial buildings, residential buildings, and public facilities. In order to improve the quality and production efficiency of aluminum honeycomb panels for building curtain walls, manufacturing technology research is needed. The following are the specific research contents:

1. Material selection

The main materials for aluminum honeycomb panels are aluminum alloy and honeycomb core material. When selecting materials, they should be determined based on specific needs and usage environments. Generally speaking, the strength of aluminum alloy is higher than that of honeycomb core material, and the degree of lightweighting of honeycomb core material is higher than that of aluminum alloy. In the manufacturing process, suitable materials should be selected according to the actual situation.

1. Production process

The production process of aluminum honeycomb panels for building curtain walls includes raw material preparation, cutting, forming, welding, and other stages. In these stages, attention should be paid to the accuracy and stability of the materials to ensure the quality of the product. Attention should also be paid to optimizing and improving the process flow to increase production efficiency and reduce costs.

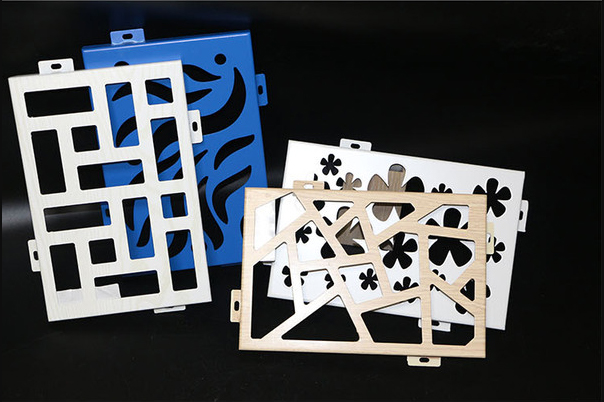

1. Surface treatment

The surface treatment of aluminum honeycomb panels for building curtain walls is an important factor affecting product quality and appearance. Common surface treatment methods include anodizing, spraying, electrophoretic coating, etc. When choosing a surface treatment method, it should be determined based on the product's purpose and usage environment. For example, if the product needs to be exposed to sunlight, a surface treatment method with good weather resistance should be chosen.

1. Quality control

Strict quality control is required for the product during the manufacturing process. This includes the selection of raw materials, control of production processes, quality of surface treatment, and other aspects. Only through strict quality control can the quality and safety of the product be guaranteed.

The research on manufacturing technology of aluminum honeycomb panels for building curtain walls is very important. Only through continuous research and improvement can the quality and production efficiency of products be improved to meet market demand.

Customer service QQ

Customer service QQ