Industry information

Company News

- Aluminum veneer, a delicate interpretation of architectural aesthetics

- Aluminum alloy air conditioning cover, the secret weapon to protect the coolness of summer!

- Aluminum veneer: the beauty of industry, the charm of simplicity

- Aluminum veneer customization, creating a new proposition for personalized space!

- Unveiling the unique charm and wide application of fluorocarbon aluminum veneer

Industry dynamics

- Aluminum alloy air conditioning cover, a great helper for cool summer!

- Ceiling paint aluminum veneer fashion home new trend

- Quality control of customized construction of aluminum veneer

- Aluminum veneer has strong anti fouling ability

- Customization process requirements for aluminum veneer

Frequently asked questions

- What is the production process of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the value of recycling and reusing aluminum veneer?

- What is the environmental performance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

5 test data on durability performance of aluminum veneer

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: February 21, 2025 19:00:03

- Click:0

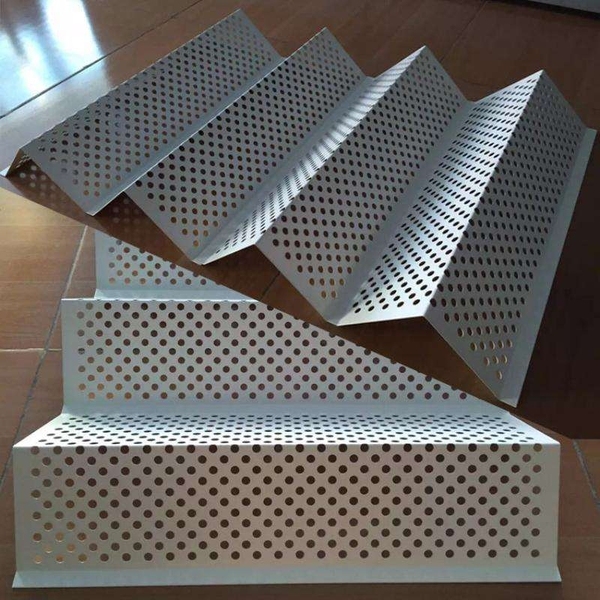

Aluminum veneer, as a new type of building material, has the advantages of lightweight, high strength, and strong decorative properties. Its durability is one of the important indicators to measure its service life and effectiveness. Next, we will introduce 5 test data on the durability performance of aluminum veneer.

1. Tensile strength test: Tensile strength refers to the maximum tensile stress that aluminum veneer can withstand under tensile force. Generally speaking, the tensile strength of aluminum veneer should be greater than or equal to 180MPa to ensure that it can withstand the influence of its own weight and other external forces.

2. Bending strength test: Bending strength refers to the maximum bending stress that aluminum veneer can withstand under bending force. Generally speaking, the bending strength of aluminum veneer should be greater than or equal to 100MPa to ensure that it can withstand the influence of its own weight and other external forces.

3. Impact strength test: Impact strength refers to the maximum impact load that aluminum veneer can withstand under the action of impact force. Generally speaking, the impact strength of aluminum veneer should be greater than or equal to 70J/m2 to ensure its ability to resist the influence of external impacts.

4. Corrosion resistance test: Corrosion resistance refers to the maximum degree of corrosion that aluminum veneer can withstand when subjected to corrosive substances. Generally speaking, the corrosion resistance of aluminum veneer should meet the requirements of national standards to ensure that it will not experience corrosion during long-term use.

5. Fire resistance test: Fire resistance refers to the flame retardant performance exhibited by aluminum veneer when subjected to flame invasion. Generally speaking, the fire resistance of aluminum veneer should meet the requirements of national standards to ensure that it will not cause fire accidents during use.

The above 5 test data on the durability performance of aluminum veneer are key factors in ensuring the service life and effectiveness of aluminum veneer. Consumers should choose products that meet these test data requirements when choosing aluminum veneer, and request relevant testing reports and certificates. It is recommended that consumers pay attention to reasonable use and maintenance when using aluminum veneer to extend its service life and maintain good aesthetics and anti-corrosion performance.

Customer service QQ

Customer service QQ