Industry information

Company News

- The Fashion Turn of Aluminum Veneer: It's Not Just About Exterior Wall Materials

- Production process and equipment selection of aluminum veneer

- Customize aluminum veneer to create your own space aesthetic

- Aluminum veneer: the "fashionable coat" of modern architecture

- Aluminum alloy air conditioning cover: a new choice for home cooling!

Industry dynamics

- The production process and equipment of aluminum veneer, measures to improve production efficiency

- Characteristics and advantages analysis of perforated roller coated aluminum veneer

- What is the durability of aluminum veneer?

- Fluorocarbon aluminum veneer: a new favorite in the construction industry, both environmentally friendly and fashionable!

- Aluminum veneer: a fashionable choice for modern architecture

Frequently asked questions

- What are the thickness and specifications of aluminum veneer?

- What are the manufacturers of aluminum veneer?

- What is the value of recycling and reusing aluminum veneer?

- How to improve the environmental performance of aluminum veneer?

- What is the corrosion resistance of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the forming processes of aluminum veneer for curtain walls?

- Author: Xinlongtai Aluminum Industry (Guangdong) Co., Ltd

- Release time: 2022-03-08 07:27:38

- Click:0

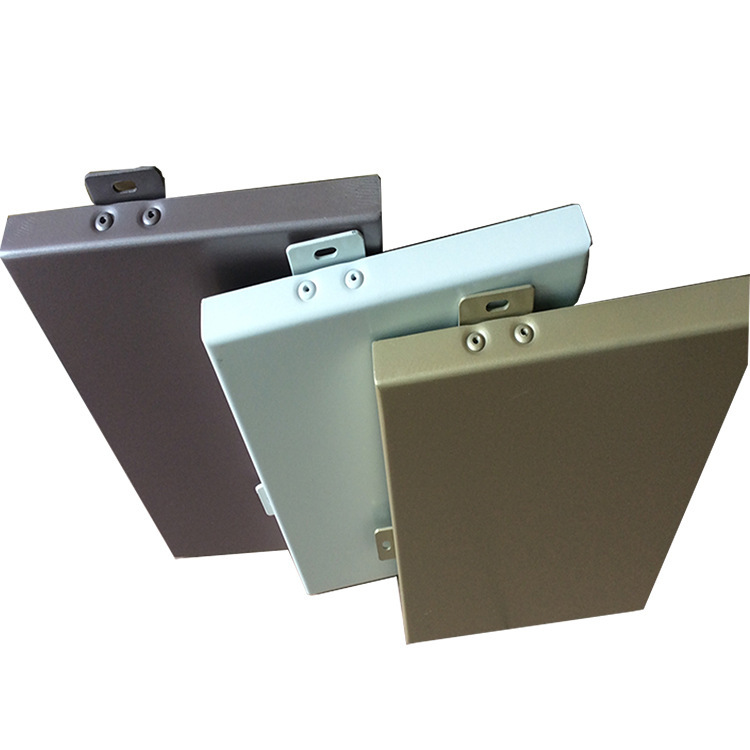

As a common exterior wall decoration material, the molding process of curtain wall aluminum veneer is also a very important indicator. The forming process of curtain wall aluminum veneer not only affects its appearance and practicality, but also directly affects the overall quality and value of the building. Below is a detailed introduction to the forming process of aluminum veneer for curtain walls.

One of the forming processes for curtain wall aluminum veneer is the use of roll forming technology. This process involves pressing aluminum alloy sheets with rollers to form the desired shape and size. Compared to traditional stamping processes, roll forming technology has higher precision and stability, and can produce more refined products.

The second forming process for curtain wall aluminum veneer is to use CNC machining technology. This process involves cutting, drilling, bending, and other processing of aluminum alloy sheets using CNC machines to achieve the desired shape and size. Compared to traditional manual processing techniques, CNC machining has higher efficiency and accuracy, and can produce more standardized products.

The third forming process of curtain wall aluminum veneer is to use laser cutting technology. This process involves cutting aluminum alloy sheets using laser to achieve the desired shape and size. Compared to traditional mechanical cutting processes, laser cutting technology has higher precision and speed, and can produce more refined products.

The fourth forming process of curtain wall aluminum veneer is to use hot pressing forming process. This process involves placing aluminum alloy sheets in a heated mold and applying pressure to form the desired shape and size. Compared to traditional cold press forming processes, hot press forming processes have higher stability and accuracy, and can produce more robust products.

The forming process of aluminum veneer for curtain walls is diverse. When selecting and using curtain wall aluminum veneer, it is necessary to conduct a comprehensive evaluation based on the actual situation, and pay attention to the quality certification, production process, and testing reports of the curtain wall aluminum veneer to ensure that it meets the relevant national standards and specifications. It is also necessary to select appropriate molding processes based on specific construction environments and climate conditions, in order to achieve better cost-effectiveness and usability.

Customer service QQ

Customer service QQ